Stainless Steel Mixing Tank

Introduction

Stainless steel mixing tanks serve as core equipment in production processes across food and beverage, biopharmaceutical, fine chemical, and cosmetic industries. They integrate multiple functions including mixing, blending, temporary storage, formulation, heating, and cooling. This equipment efficiently processes various fluids, pastes, and high-viscosity slurries within a highly clean and controllable environment, forming a crucial foundation for ensuring product uniformity, stability, and hygienic safety.

Wanzhi Machinery stainless steel mixing tanks feature large capacities, corrosion-resistant materials, easy cleaning, and extended service life. Beyond mixing tanks, our product range includes filling machines, stainless steel reactors, and stainless steel water storage tanks.

- Capacity: 50-4000L

- Material: 304 or 316L Stainless Steel

Working Principle

The core function of stainless steel mixing tanks is achieved through “power transmission + agitator action,” ensuring uniform mixing or processing of materials within the tank. The overall process consists of three steps:

- The motor provides power, which is adjusted for speed and torque via a reducer. This power is then transmitted through a drive shaft to rotate the agitator inside the tank (e.g., paddle-type, anchor-type);

- As the agitator rotates, it induces shear, convection, or diffusion within the tank contents, disrupting material stratification to achieve uniform mixing, dissolution, or blending;

- For heating/cooling requirements, heat/cold sources can be introduced through the tank jacket or internal coils to simultaneously regulate material temperature during agitation.

Technical Parameters

| Model | WZ01-50 | WZ01-100 | WZ01-150 | WZ01-250 | WZ01-300 | WZ01-500 | WZ01-600 | WZ01-1000 | WZ01-1200 | WZ01-1500 | WZ01-2000 | WZ01-2500 | WZ01-3000 | WZ01-4000 |

| Specifications (L) | 50 | 100 | 150 | 250 | 300 | 500 | 600 | 1000 | 1200 | 1500 | 2000 | 2500 | 3000 | 4000 |

| Cylinder Diameter (mm) | 400 | 500 | 600 | 600 | 700 | 800 | 900 | 1000 | 1100 | 1200 | 1200 | 1400 | 1500 | 1600 |

| Cylinder Height (mm) | 400 | 500 | 500 | 800 | 800 | 950 | 950 | 1200 | 1200 | 1200 | 1500 | 1500 | 1500 | 1800 |

| H1 (Discharge Port to Ground) | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 350 | 350 | 350 | 350 |

| Power | 0.37 | 0.37 | 0.37 | 0.55 | 0.55 | 0.55 | 0.55 | 0.75 | 0.75 | 0.75 | 1.5 | 1.5 | 2.2 | 4 |

| Stirring Speed | 36 r/min | |||||||||||||

| Operating Pressure | ≤0.09MPa | |||||||||||||

| Operating Temperature | < 160 ℃ | |||||||||||||

| Inner liner material | 304 or 316L | |||||||||||||

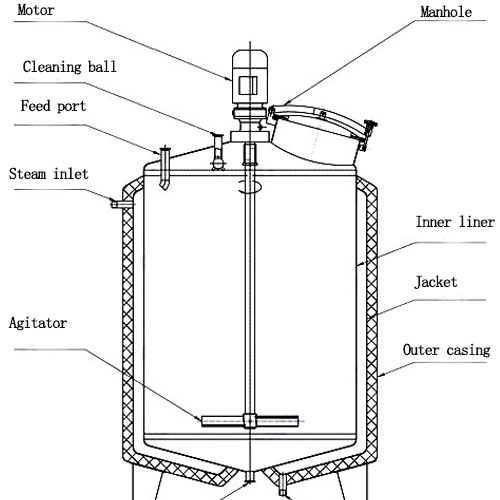

Structure of Stainless Steel Mixing Tanks

- Motor: Provides primary power to drive the agitator blades, achieving mixing and blending of materials within the tank.

- Cleaning Ball (CIP Ball): The equipment’s “automatic cleaner,” installed at the top of the tank.

- Feed Port: The “entry point” for materials. Typically designed on the top or side of the tank.

- Steam Inlet: The “channel” for heat. Connects to an external steam source, directing steam into the jacket (or inner liner cavity) to heat the contents via heat transfer.

- Agitator (impeller): Rotates to uniformly mix different ingredients within the tank, or to achieve dispersion, dissolution, and suspension of materials.

- Manhole: A sufficiently large opening allowing operators to enter the tank for inspection, maintenance, or thorough manual cleaning.

- Inner Tank: Constructed from stainless steel (e.g., 304/316L), it directly contacts the material.

- Jacket: The “temperature controller.” Enveloping the outer surface of the inner tank, it forms a cavity space for circulating steam (heating), cold water, or coolant (cooling).

- Outer Casing: The “insulation layer.” Covering the exterior of the jacket, it primarily protects the jacket and isolates it from the external environment.

Options

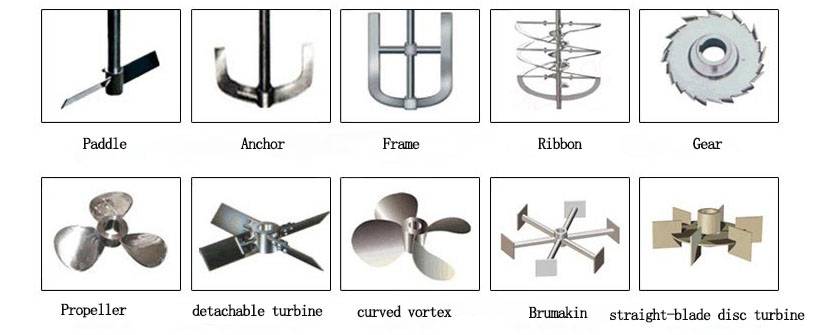

- Agitator Types: Paddle, Anchor, Frame, Ribbon, Gear, Propeller, Detachable Turbine, Curved Vortex, Brumakin, and Straight Disc Turbine.

- Other Options: Reducer, Heater, Valve, Sight Glass, Sanitary Pump, Mechanical Seal, Instrumentation, and Vacuum Pump.

Stainless Steel Mixing Tank Application

| Industries | Application Scenarios |

| Food and Beverages | Mix and stir sauces (such as ketchup and fermented soybean paste), beverages (such as juice and yogurt), condiments, and candy and pastry ingredients. |

| Pharmaceuticals | Mix ointments, liquid medicines, and traditional Chinese medicine decoctions, and dissolve and homogenize pharmaceutical raw materials for vaccine production. |

| Cosmetics | Emulsify and mix creams, lotions, serums, shampoos, and conditioners. |

| Chemicals | Mix paints, adhesives, and resins, as well as process acid and alkali solutions, lubricants, and other chemical raw materials. |

| Building Materials | Mix paints, putty powder, waterproofing materials, concrete additives, and other materials to ensure uniform composition. |

Our SS Mixing Tanks Advantages

- Flexible Customization: Capacities range from 50L to 4000L, and we can design and manufacture them to meet specific customer needs. We feature quick-release chuck-type connections, and the exterior can be polished or brushed to suit various production scenarios and aesthetic preferences.

- High-Quality Materials and Craftsmanship: The tank’s interior is constructed of corrosion-resistant and hygienic 304 or 316L stainless steel, with a mirror-polished interior surface accuracy of Ra ≤ 0.28μm-0.6μm. It resists sticking and is easy to clean, meeting the high standards of the food and pharmaceutical industries.

- Comprehensive Functionality: We can flexibly add heating, cooling, high- and low-speed mixing, sealing, pressure-bearing, vacuum, and metering systems to suit your production process, providing a one-stop solution for complex material mixing, temperature control, and metering needs.

- Precise Mixing: We can customize the design of various impeller configurations, including turbine, paddle, and anchor, to suit different material characteristics and mixing objectives, ensuring uniform mixing and achieving the desired mixing effect.

What tank combinations can the SS mixing tank be combined with?

- SS Mixer tank + colloid mill: Achieve ultrafine material reduction.

- SS Mixing tank + Filling machine: Completes integrated “mixing → portioning” operations.

- SS Mixing tank + Homogenizer tank / Homogenizer: Enhances material stability.

- SS Mixing tank + Filter: Ensures material purity.

- SS Mixing tank + SS Reactor: Meets combined “mixing + reaction” requirements.

Related Products

Stainless Steel Floating Roof Tank

Stainless Steel Floating Roof Tank Introduction In winemaking, the thoroughness of fermentation and the stability…

Stainless Steel Wine Cold Stabilizer Tank

Stainless Steel Wine Cold Stabilizer Tank Introduction Stainless Steel Wine Cold Stabilization Tank, also known…

Stainless Steel Wine Storage Tanks

Stainless Steel Wine Storage Tanks Introduction Wine storage tanks are indispensable storage equipment in the…

Stainless Steel Wine Fermentation Tanks

Stainless Steel Wine Fermentation Tanks Introduction Stainless steel wine fermentation tanks are essential equipment for…

Beer Fermentation Tank

Beer Fermentation Tank Beer fermentation tanks Introduction This stainless steel beer fermentation tank is a…

Contact Us