Milk Cooling Tank

Introduction

Refrigeration tanks are the preferred equipment for preserving raw milk on farms. Utilizing rapid cooling technology and rigorous hygiene standards, they safeguard milk quality from the source and help optimize farm revenue

Wanzhi Machinery offers milk cooling tanks in various capacities to meet varying milk production needs. They utilize direct cooling technology, with the tank’s inner and outer shell constructed of food-grade 304 stainless steel and insulated with rigid polyurethane, ensuring hygienic and environmentally friendly cooling performance.

- Capacity range: 500L – 20,000L

- Material: Food-grade stainless steel

Technical Parameters

| Effective capacity | 500L | 1000L | 2000L | 3000L | 5000L | 6000L | 8000L | 10000L | 12000L | 15000L | 20000L | |

| Maximum capacity | 510L | 1010L | 2010L | 3050L | 5100L | 6300L | 8200L | 10600L | 12500L | 15500L | 20000L | |

| Type | Horizontal Oval / Vertical | |||||||||||

| Cooling method | Direct cooling | |||||||||||

| Material | Food-grade stainless steel | Inner Tank: 2.0mm, Outer Wall: 1.5mm | Inner Tank: 2.5mm, Outer Wall: 2.0mm | Inner Tank: 3.0mm, Outer Wall: 2.0mm | ||||||||

| Evaporator | Evaporation area (㎡) | 1.43 | 1.92 | 3.76 | 4.75 | 5.84 | 6.56 | 9.02 | 11.28 | 13.52 | 17.04 | 19.04 |

| Material | 304 | |||||||||||

| Viewing hole diameter (mm) | 400 | 450 | ||||||||||

| Milk outlet diameter (mm) | 50 | |||||||||||

| Dimensions (L*W*H) (mm) | 2100*1000*1300 | 2200*1300*1450 | 3200*1500*1500 | 3400*1700*1700 | 3760*2200*2100 | 4050*2200*2100 | 4950*2300*2100 | 5940*2200*2100 | 6460*2200*2100 | 6900*2300*2400 | 650022002300(split) | |

| Insulation material and thickness (mm) | Rigid polyurethane, 80mm | |||||||||||

| Insulation performance | Complies with GB/T10942-2001 standard | |||||||||||

| Refrigeration time | Complies with GB/T10942-2001 standard | |||||||||||

| Compressor | Refrigerant type | R22 | ||||||||||

| Total power (kW) | 1.5 | 3 | 3.75 | 4.5 | 9 | 9 | 12 | 15.5 | 17.5 | 24 | 28 | |

| Compressor protection device | Pressure controller protection, compressor midpoint protection, overcurrent protection, phase sequence protection | |||||||||||

| Mixing system | Power (kW) | 0.37 | 0.75 | 0.75*2 | 0.75*3 | 0.75*4 | ||||||

| Rpm(r/min) | 36 | |||||||||||

| Stirring blade size (mm) | 630*150 | |||||||||||

| Shaft Diameter (mm) | 32 | |||||||||||

| Control Method | Manual/Automatic | |||||||||||

| Number of cleaning nozzles | 1 set | 2 sets | 3 sets | |||||||||

| Control box | Temperature risplay | Digital display (00.0°C) | ||||||||||

| Temperature display range | 0-99℃ | |||||||||||

| Set temperature adjustment range | 0-8℃ | |||||||||||

| Temperature deviation | ±0.5℃ | |||||||||||

| Power supply | Main power supply | 220V, 50Hz | 380V, 50Hz | |||||||||

| Control power supply | 220V | 380V | ||||||||||

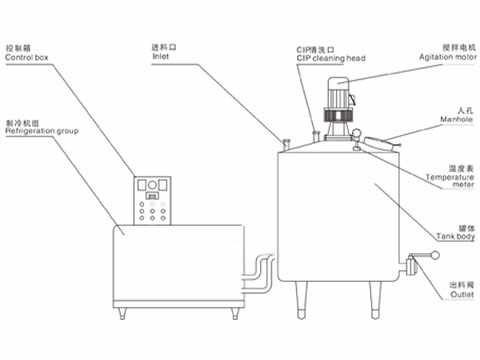

Milk Cooling Tank Structure

- Refrigeration System: The refrigeration system includes a compressor, evaporator, condenser, and filter drier.

- Compressor: The “heart” of the refrigeration system, responsible for driving the refrigerant through the system and compressing it into high-temperature, high-pressure gas.

- Evaporator: As the cooling component of the system, it directly or indirectly exchanges heat with the milk, absorbing heat from the milk and rapidly reducing its temperature.

- Condenser: Cools the high-temperature, high-pressure gas discharged from the compressor into a liquid state, releasing heat (a core heat dissipation component).

- Stirring System: Ensures a uniform temperature within the tank, preventing fat from rising and localized freezing, and assists with the cleaning process.

- Controller: The intelligent brain of the device, responsible for setting, monitoring, and automatically adjusting temperature, stirring, and cleaning operations, ensuring precise and reliable operation.

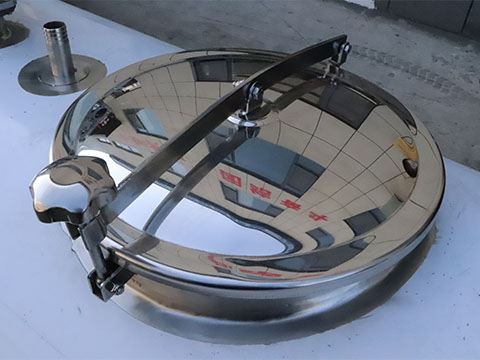

- Viewing port: Allows direct inspection of the milk level, status, and cleaning status within the tank without opening the lid, facilitating daily inspections.

- CIP cleaning port: A standard connection for connecting cleaning lines, key to automated in-place cleaning (CIP) and ensuring complete hygiene within the tank.

Component Image

Wanzhi Milk Cooling Tank Advantages

- Precise Match, Flexible and Efficient: We offer a variety of capacities to precisely meet the varying production and space requirements of businesses, from small farms to large dairy operations.

- Energy-Efficient & Environmentally Friendly: Features eco-friendly high-density polyurethane insulation that effectively blocks heat exchange, minimizes cold loss, and significantly reduces operational energy consumption. Maintains stable low-temperature conditions inside the tank even during external temperature fluctuations.

- Ultimate Hygiene, Safe and Reliable: Both inner tank and outer shell are constructed from food-grade 304 stainless steel with smooth, seamless surfaces. This design minimizes milk residue buildup and bacterial growth while facilitating effortless daily cleaning.

- Intelligent Control, Hassle-Free Operation: Choose from basic to fully automated intelligent control systems. These precisely regulate cooling temperatures, support automatic cleaning cycles, and enable real-time operation monitoring—reducing manual intervention and operational errors.

We supply not only individual milk cooling tanks, but also production lines for condensed milk. The milk cooling tank is just one piece of equipment in a condensed milk production line. Please contact us for details about condensed milk production lines or any related equipment.

Related Products

Stainless Steel Floating Roof Tank

Stainless Steel Floating Roof Tank Introduction In winemaking, the thoroughness of fermentation and the stability…

Stainless Steel Wine Cold Stabilizer Tank

Stainless Steel Wine Cold Stabilizer Tank Introduction Stainless Steel Wine Cold Stabilization Tank, also known…

Stainless Steel Wine Storage Tanks

Stainless Steel Wine Storage Tanks Introduction Wine storage tanks are indispensable storage equipment in the…

Stainless Steel Wine Fermentation Tanks

Stainless Steel Wine Fermentation Tanks Introduction Stainless steel wine fermentation tanks are essential equipment for…

Beer Fermentation Tank

Beer Fermentation Tank Beer fermentation tanks Introduction This stainless steel beer fermentation tank is a…

Contact Us