Plant Oil Extractor

Introduction

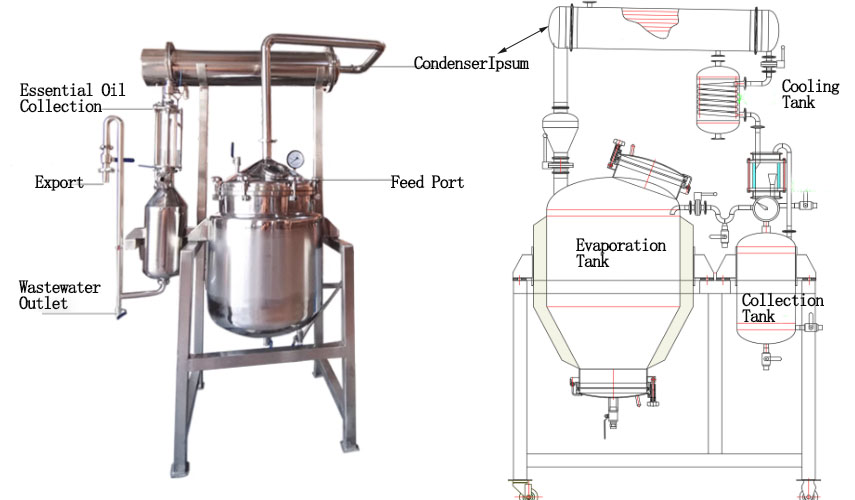

Plant Oil Extraction Equipment is a modern apparatus specifically designed to extract high-purity essential oils and hydrosols from aromatic plants. Utilizing advanced steam distillation technology, this equipment employs scientific structural design and precise process control to ensure the preservation of natural components while enhancing extraction efficiency. It finds extensive application in the cosmetics, aromatherapy, food flavoring, and pharmaceutical industries.

- Volume: 50 – 2000L

- Material: SUS304

- Essential Oil Extractor User Manual

Working Principle

The equipment supports three distillation methods: water-over-oil distillation, water-in-oil distillation, and direct steam distillation. The workflow is as follows:

- Loading Stage: Pre-processed plant material is loaded into the extraction tank;

- Heating and Distillation: The steam system is activated, with steam passing through the plant layer;

- Component Release: Thermal energy ruptures plant glands, releasing essential oil molecules;

- Vapor Transport: Essential oil molecules rise with steam vapor into the condensation system;

- Condensation Conversion: Hot steam cools in the condenser, forming an oil-water mixture;

- Separation Collection: The mixture enters the oil-water separator, where essential oil and hydrosol automatically separate by layering;

- Circulation Optimization: Adjustable water flow recirculates to the extraction tank for repeated distillation, enhancing extraction efficiency.

Technical parameters

| Model Number | WZ-50 | WZ-100 | WZ-300 | WZ-500 | WZ-1000 | WZ-2000 |

| Extraction Tank Volume | 50L | 100L | 300L | 500L | 1000L | 2000L |

| Extraction Tank Inner Diameter | 400mm | 600mm | 700mm | 800mm | 1000mm | 1400mm |

| Extraction Tank Jacket Diameter | 500mm | 700mm | 800mm | 900mm | 1100mm | 1500mm |

| Temperature | 60-100°C | |||||

| Steam Consumption | 5kg/h | 10kg/h | 30kg/h | 50kg/h | 100kg/h | 200kg/h |

| Vacuum Pump Power | 1.1KW | 1.5KW | 2.2KW | 3KW | 4KW | 4KW |

| Electric Heating Power | 2*3KW | 2*6KW | 3*6KW | 4*6KW | 4*9KW | 4*12KW |

| Cooling Water Consumption | 500kg/h | 500kg/h | 1000kg/h | 1000kg/h | 2000kg/h | 5000kg/h |

| Extraction Time | 0.5-1h | |||||

| Heat Exchange Area | 1㎡ | 2㎡ | 6㎡ | 8㎡ | 10㎡ | 15㎡ |

| Diameter × Height | 0.5*1.5m | 0.8*1.6m | 0.9*1.8m | 1.0*1.9m | 1.2*2.5m | 1.6*3.0m |

Structural Composition

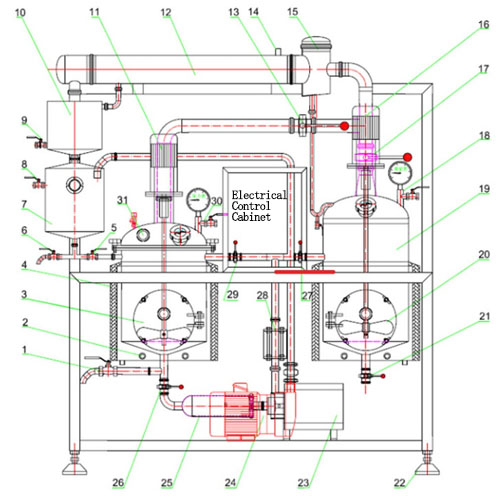

1.Sampling valve; 2. Heater; 3. Sludge discharge port; 4. Polyurethane insulation layer; 5. Reflux valve; 6. Distilled water recovery valve; 7. Oil-water separator; 8. Drain valve;

9. Cooling water inlet; 10. Cooler; 11. Agitation motor; 12. Condenser; 13. Extraction bypass valve; 14. Condensate outlet; 15. Gas-liquid separator;

16.Agitation motor; 17. Concentration bypass valve; 18. Vent valve; 19. Concentration tank; 20. Agitation blades; 21. Discharge port; 22. Leveling feet; 23. Material pump;

24. Vacuum pump; 25. Pipeline filter; 26. Discharge valve; 27. Concentration tank feed valve; 28. Pipeline sight glass; 29. Heat reflux valve; 30. Vent valve; 31. Feed inlet

The structural composition of different plant essential oil extractors varies. However, the main components remain consistent while their positions may be adjusted. We offer customization services. Alternatively, specify your application or production volume, and we will recommend the most suitable extractor for your needs. Contact us to discuss your requirements.

Extractable Plant Species and Applicable Industries

Plant Oil Extractor Extractable Plants

The equipment accommodates over 50 aromatic plant species, encompassing various raw materials such as flowers, leaves, roots, bark, and fruits. Distillation parameters (steam pressure, duration) can be adjusted according to plant characteristics to achieve optimal extraction results. Primary plant classifications are as follows:

- Floral Plants: Rose, Lavender, Chamomile, Jasmine, Orange Blossom, Ylang-Ylang, etc.

- Leaves & Herbs: Rosemary, Mint, Basil, Lemongrass, Eucalyptus, Tea Tree, Bay Leaf, Thyme, etc.

- Woody & Resinous Plants: Sandalwood, Cedarwood, Frankincense, Myrrh, Juniper, Cypress, etc.

- Roots, Rhizomes & Seeds: Ginger, Angelica, Star Anise, Cinnamon, Coriander, Fennel, Nutmeg, etc.

Plant Oil Extractor Application Industries

- Cosmetics Industry: Supplies natural fragrances and active ingredients.

- Aromatherapy: Produces therapeutic-grade essential oils.

- Food & Beverage: Natural edible flavor extraction.

- Pharmaceutical Industry: Active ingredient extraction from herbal medicines.

- Personal Care Products: Natural additives for cleansing and care products.

Equipment Features and Advantages

- Materials and Manufacturing Standards: Food-grade stainless steel SUS304 with mirror-polished inner walls; mirror or matte finish on outer surfaces, compliant with GMP and QS certification requirements; all contact parts utilize corrosion-resistant materials.

- Operational & Safety Features: High automation for simplified operation; equipped with multiple safety interlock devices; pneumatic system operating pressure 0.7MPa; visual inspection window for convenient monitoring.

- Efficiency & Quality Assurance: Recovery efficiency exceeding 95%; essential oil yield increased by 15-30% compared to traditional methods; essential oil quality meets international aromatherapy standards.

Why Choose Us?

- Material Compliance for Peace of Mind: Food-grade 304 stainless steel construction with mirror-polished inner walls meets GMP, QS, and other standards, suitable for export requirements.

- Energy Efficiency and Cost Savings: Direct steam heating + 50mm thick insulation layer + multi-program condensation reduces energy consumption below industry averages while shortening extraction time.

- Flexible Adaptability for All Scenarios: Available in 1-10m³ capacities, compatible with over 50 plant species, suitable from lab R&D to industrial-scale production lines.

- Customization Support: Flexibly adjust equipment layout and functional modules based on your production space and capacity planning, providing tailored solutions.

Wanzhi Machinery is a professional extraction equipment supplier in China with over 14 years of production and export experience. Certified under ISO 9001 and CE standards, we are a trusted provider of mechanical products. For any extraction equipment needs, please contact us for details.

Related Products

Extraction and Concentration Unit

Heat Reflux Extraction and Concentration Unit Introduction The Thermal Reflux Extraction and Concentration Unit is…

Stainless Steel Spherical Evaporator

Stainless Steel Spherical Evaporator Introduction The stainless steel spherical evaporator, also known as a spherical…

Small Extraction, Concentration

Small Extraction, Concentration, and Filtration Machine Introduction This highly integrated, comprehensive, multifunctional process equipment integrates…

Honey Concentrator

Honey Concentrator Introduction The honey concentrator is a core piece of equipment in honey processing….

Contact Us