stainless steel reactor

Introduction

Stainless steel reactors are sealed containers made of stainless steel. They perform chemical reactions, physical mixing, heating/cooling, stirring, and separation processes under controlled temperature, pressure, and stirring rate.

Wanzhi Machinery’s stainless steel reactors are manufactured from SS304 stainless steel (SS316 optional) and offer a wide range of capacities. They are safe, efficient, and environmentally friendly.

- Capacity: 1L – 300L

- Material: SS304 stainless steel (SS316 optional)

Working Principle

The core operating principle of a stainless steel reactor is a closed pressure vessel constructed primarily of stainless steel (commonly SUS304/SUS316L). By controlling key conditions such as temperature, pressure, and agitation, a stable reaction environment is created for the materials, achieving process objectives such as chemical reactions, physical mixing, or material modification. This process can be broken down into three key steps:

- Material Reaction Environment Creation: The raw materials to be reacted are added proportionally into a stainless steel kettle. Depending on the process requirements, the reaction chamber is either sealed (to prevent volatilization and contamination) or semi-open.

- Key Condition Control: A supporting system is used to adjust the required reaction parameters—temperature, pressure, and mixing efficiency (a built-in agitator rotates to ensure uniform contact between the materials and increase the reaction rate).

- Reaction process and product processing: Under the specified temperature, pressure, and stirring conditions, the materials undergo chemical reactions or physical changes. Upon completion, the products are discharged through the discharge port, and the kettle is then cleaned to complete a single process cycle.

Technical Parameters

| Product Model | SS-1L | SS-2L | SS-3L | S212-5L |

| Capacity | 1L | 2L | 3L | 5L |

| Jacket dimensions | 1L | 1.5L | 1.5L | 2L |

| Product Model | SS-10L | SS-20L | SS-30L | S212-50L |

| Capacity | 10L | 20L | 30L | 50L |

| Jacket dimensions | 5L | 10L | 12L | 30L |

| Product Model | SS-100L | SS-150L | SS-200L | S212-300L |

| Capacity | 100L | 150L | 200L | 300L |

| Jacket dimensions | 58L | 68L | 70L | 30L |

| Material | SS304 stainless steel (SS316 optional) | |||

| Thickness | Inner lining: 4mm, outer shell: 4mm (customizable based on pressure) | |||

| Motor power | 120W | |||

| Speed | 0~600rpm | |||

| Controller | Speed adjustment, LCD display for temperature and speed | |||

| Voltage | 110V/220V, 50/60Hz | |||

| Working pressure | -1 – 0.49MPa | |||

| Vacuum seal | 0.098MPa | |||

| Cap | Nine ports (customizable based on requirements) | |||

| Constant pressure drop funnel | Stainless steel 250ml | |||

| Condenser | Stainless steel shell and tube condenser | |||

| Drain valve | DN25 ball valve | DN32 ball valve | ||

| Frame | 304 stainless steel | |||

| Inlet/outlet oil ports | DN15 male thread | |||

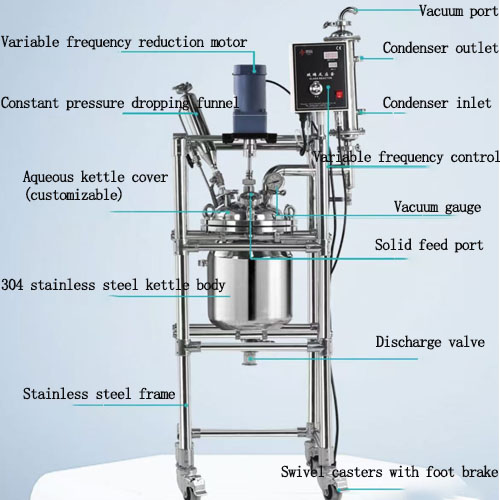

Functions of Stainless Steel Reactor Components

- Stainless Steel Reactor Body: The core container of the reactor, serving as the space for mixing and reacting materials.

- Reactor Lid: Seals the reactor body, creating a closed reaction environment. It features various ports for installing other components.

- Variable Frequency Drive Motor + Variable Frequency Controller: The variable frequency drive motor powers the stirring system, while the variable frequency controller adjusts the motor speed.

- Vacuum Port + Vacuum Gauge: The vacuum port can be connected to a vacuum pump to extract air from the reactor, while the vacuum gauge monitors the negative pressure in real time.

- Solid Feed Port: An opening, usually with a lid, specifically designed for feeding solid materials such as powders and granules.

- Discharge Valve: Located at the bottom of the reactor, discharges materials after the reaction is complete.

- Constant Pressure Dropping Funnel: Attached to the reactor lid, the constant pressure dropping funnel is a special feeding device.

- Condenser Inlet + Condenser Outlet: The condenser inlet allows the cooling medium to flow in, while the outlet discharges the heated medium. The condenser can be connected to the reactor body.

- Stainless steel frame: Serves as the entire reactor’s supporting framework, securing and supporting all components, including the reactor body and motor, ensuring stability.

- Universal casters with foot brakes: Allow for easy movement of the entire reactor and, once in place, secure it with a foot brake to prevent slipping during operation.

More Informatio

Advantages of Stainless Steel Reactors

- Excellent Corrosion Resistance: 304/316L stainless steel is resistant to acids, alkalis, and chemical solvents, extending equipment life.

- Easy Cleaning and Maintenance: The smooth surface of stainless steel resists adhesion, making it easy to clean and maintain.

- Versatility: By equipping various devices, it can perform a variety of processes, including synthesis, mixing, extraction, and emulsification.

- Excellent Mechanical Properties: High strength and toughness, it can withstand high temperatures and pressures, meeting most reaction conditions.

Applications of Stainless Steel Reactors

- Chemical Industry: Used for processes such as synthesis, polymerization, and hydrolysis to produce chemical products, dyes, and pigments.

- Pharmaceutical and Biological Industries: Used for drug synthesis and biofermentation to produce pharmaceuticals and biological products.

- Food Processing: Used for brewing, boiling, and emulsification to produce beverages, food additives, candies, and edible oils.

- Cosmetics Production: Core for emulsification processes to create creams, lotions, lipsticks, and other products.

Related Products

Multi Vegetable Cutter

Multi Vegetable Cutter Multi-functional vegetable cutter Introduction This commercial dual-head multi-function vegetable cutter is a…

Commercial Dual-Inverter Vegetable Cutter

Commercial Dual-Inverter Vegetable Cutter Commercial Dual-Inverter Vegetable Cutter Introduction This commercial dual-inverter automatic vegetable cutter…

Dual-speed Meatball Forming Machine

Dual-speed Meatball Forming Machine High-speed meatball forming machine Introduction The WZ-702 Dual-Speed Meatball Former is…

Commercial Meatball Forming Machine

Commercial Meatball Forming Machine Introduction Wanzhi Machinery’s WZ-605/605S compact commercial fully automatic meatball forming machine…

Potato Peeler Machine

Commercial Potato Peeler Introduction This commercial potato peeler is specifically designed for efficient and hygienic…

Contact Us