tomato sauce Production Line

Designed for small and medium investors, featuring a compact footprint and minimal investment. Capable of producing ketchup and a variety of sauce products.

Tomato Sauce Production Line Prospects

Tomato sauce ranks among the world’s most popular condiments, with its market value experiencing sustained growth. While mature markets like North America and Europe maintain steady expansion, Asia, Latin America, and the Middle East have emerged as the fastest-growing regions.

The sustained growth in demand for tomato sauce makes investing in its production a sound choice. We offer a compact, easy-to-operate tomato sauce production line suitable for small-to-medium food processing enterprises, large cafeterias, and chain restaurants.

All equipment (parts in contact with materials) is constructed from stainless steel, ensuring easy cleaning, high hygiene standards, large capacity, high efficiency, and broad applicability. By replacing certain components, the line can accommodate cross-seasonal, multi-product production of items like carrot sauce, strawberry jam, chili sauce, and blueberry sauce.

Small-Scale Tomato Sauce Production Line Process Flow

1. Tomatoes Selection

Premium tomatoes are hand-sorted to remove substandard fruits, ensuring freshness and consistent quality.

2. Washing

Bubble washing technology thoroughly removes surface impurities, pesticide residues, and microorganisms, guaranteeing ingredient purity.

3. Crushing

Professional crushing equipment processes tomatoes into a uniform pulp, laying the foundation for subsequent steps.

4.Pulping

Employing a two-stage pulping process to precisely separate skins and seeds, yielding a smooth, pure tomato base.

5. Refining

Utilizing colloid mills for ultra-fine processing to enhance texture and optimize taste.

6. Concentration

Applying temperature-controlled evaporation technology to precisely reduce moisture content, concentrating natural flavors to achieve standard viscosity.

7. Sterilization

Ensures product safety through pasteurization while maximizing nutrient retention.

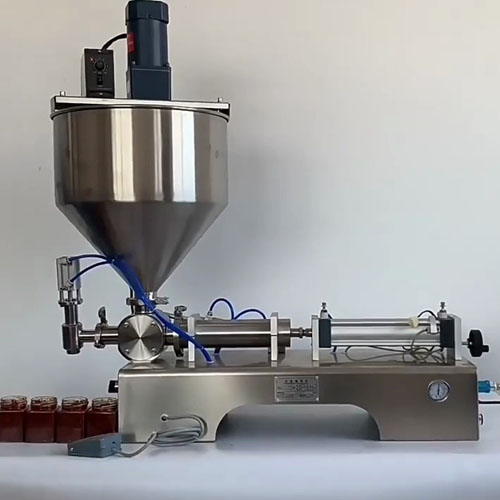

8.Packaging

Automated filling for diverse packaging formats per market demand, guaranteeing hygiene and visual appeal.

Equipment Required

Multi-Product Capability

Our Advantages

Other production lines and equipment

Contact Us