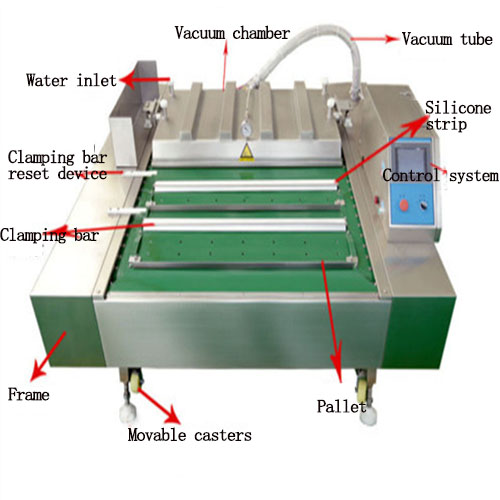

Rolling Vacuum Packaging Machine

Introduction

The rolling vacuum packaging machine is an automated vacuum packaging device suitable for continuous, high-volume production. Through processes such as vacuum extraction and sealing, it achieves preservation effects including freshness retention, moisture resistance, mold prevention, rust protection, insect deterrence, and contamination prevention, effectively extending product shelf life. It is widely used across multiple industries.

- Output: 8,000–15,000 bags

- Packaging Film Width: 1000mm

- Packaging Height: 100mm

- Packaging Format: Bagged

Working Principle

The rolling vacuum packaging machine employs a combination of chain drive and rolling conveyance to achieve automated continuous operation. The workflow primarily includes:

- First, lay the packaging bags containing items flat on the conveyor belt. The forward rolling motion of the belt precisely feeds the items beneath the vacuum chamber;

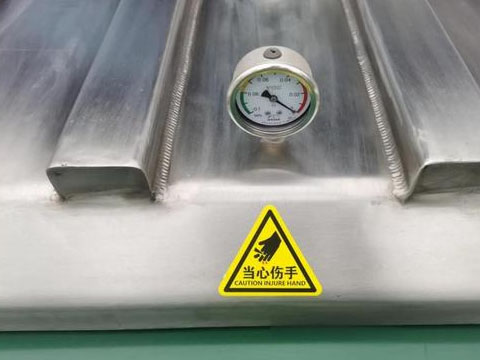

- The vacuum chamber then automatically descends, initiating the vacuum extraction process. Upon reaching the preset vacuum level, the machine automatically performs the heat-sealing operation;

- After sealing is complete, the water-cooling system promptly activates to cool the seal, preventing damage. The chamber then undergoes venting and rises to its reset position;

- Finally, the conveyor belt continues forward motion, transporting the finished packaged products to the unloading area, completing the continuous vacuum packaging operation cycle.

Technical parameters

| Model | WZ-1000 | WZ-1100 |

| Vacuum Chamber Size | 1130x500mm | 1130x500mm |

| Effective Sealing Size | 1000x10mm x 2 strips | 1000x10mm x 2 strips |

| Overall Dimensions | 1580x1800x1500mm | 1580x1900x1500mm |

| Number of Heat Sealing Strips | Single seal: 1 strip; Double seal: 2 strips | Single seal: 1 strip; Double seal: 2 strips |

| Heat Strip Spacing | Single seal: 480mm; Double seal: 230mm | Single seal: 480mm; Double seal: 230mm |

| Efficiency | 120-200 cycles/hour | 120-200 cycles/hour |

| Total Weight | 500-700kg | 500-700kg |

| Minimum Absolute Pressure | ≤200pa | ≤200pa |

| Average Power Consumption | 3KW | 3KW |

| Power Supply | 380V/50Hz | 380V/50Hz |

| Output | 8000 – 15000 bags | |

Structural Composition

The core structure of the rolling vacuum packaging machine revolves around transmission, vacuum processing, sealing, control, and auxiliary functions, primarily including:

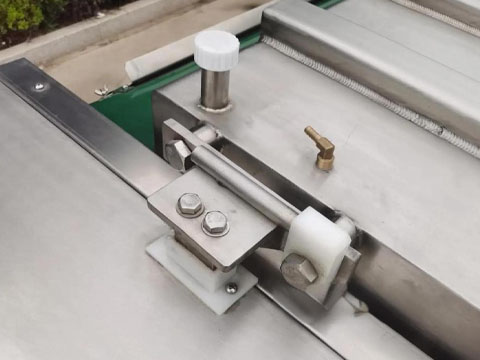

- Rolling Conveyor System: Utilizes precision chains and conveyor belts for smooth transportation;

- Vacuum Chamber and Sealing System: Fully sealed design ensures effective vacuum extraction;

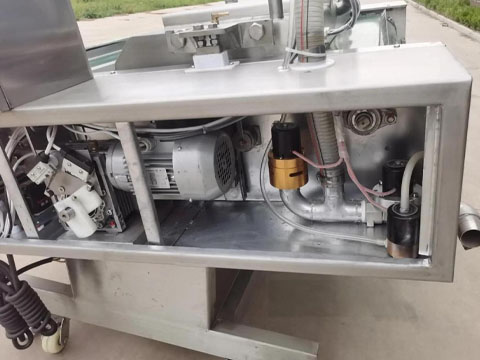

- Vacuum Pumping Unit: Equipped with a high-efficiency vacuum pump to rapidly achieve the required vacuum level;

- Heat Sealing and Cooling System: Capable of heating for sealing and water-cooling for shaping, ensuring flat and secure seals;

- Control System: Automated operation with adjustable parameters such as vacuum time and sealing temperature;

- Support and Frame Structure: Sturdy body design suitable for extended continuous operation.

Features and Advantages of the Rolling Vacuum Packaging Machine

- High-Efficiency Continuous Operation: The rolling conveyor system enables uninterrupted production, making it ideal for high-volume packaging.

- Versatile Adaptability: Capable of packaging items in various forms, including solids, granules, powders, pastes, and liquids.

- Superior Sealing Performance: The integrated water-cooled circulation system ensures smoother, more aesthetically pleasing seals, enhancing both the appearance and sealing integrity of finished packages.

- Stable Operation: Brake motors and low-speed positioning control ensure smooth lifting with minimal noise.

- Easy Cleaning & Maintenance: Fully sealed structure with water-rinse design maintains hygiene effortlessly.

- Energy-Efficient & High-Performance: Advanced vacuum pumps and sealing mechanisms boost productivity while reducing packaging costs.

What Products Can Be Packaged

- Food Industry: Freshness packaging for meat, sauces, seasonings, dried fruits, seafood, fruits and vegetables, cooked foods, soy products, snacks, etc.;

- Pharmaceuticals & Health Products: Moisture-proof and oxidation-resistant packaging for medicines, medicinal herbs, pharmaceutical preparations, health supplements, etc.;

- Chemicals & Daily Chemicals: Sealed protection for pigments, dyes, cosmetics, chemical raw materials, etc.;

- Hardware & Electronics: Rust-proof and corrosion-resistant packaging for components, measuring tools, precision parts, etc.;

- Other: Agricultural products, scientific specimens, important archives, and other items requiring long-term preservation.

Why Choose Us?

- Equipment features precision transmission and stable vacuum systems, ensuring smooth continuous operation, secure and flat seals, and significantly extended product shelf life.

- Widely compatible with various materials and packaging sizes, particularly adept at handling large items. Its robust structure and ease of cleaning/maintenance effectively ensure high uptime.

- Not only does it optimize your long-term operational costs by boosting efficiency and reducing failures, but you also gain tailored support based on our extensive manufacturing expertise.

As a fully integrated, internationally certified enterprise (ISO 9001, ISO 14001, CE, etc.) under the Wanzhi Steel Group, we guarantee the reliable quality of every machine and piece of equipment, positioning us as your trusted partner.

Related Products

Rib/Frozen Meat Slicer

Rib/Frozen Meat Slicer Introduction The Commercial Electric Rib/Frozen Meat Slicer is a CNC fully automatic…

Large Rib Cutting Machine

Large Rib Cutting Machine Introduction As a core piece of equipment in commercial meat processing,…

Commercial Single-Head Multi-Function Vegetable Cutter

Commercial Single-Head Multi-Function Vegetable Cutter Multi-functional vegetable cutter Introduction This product is a single-head multi-function…

Tanzanian Customer Purchases One Oil Press Machine

Tanzanian Customer Purchases One Oil Press Machine production completed Procurement Overview Product Name: Small Commercial…

Small Horizontal Oil Press Machine

Small Horizontal Oil Press Machine Small horizontal oil press Introduction This compact electric horizontal oil…

Contact Us