Double-Chamber Vacuum Packaging Machine

Introduction

The double-chamber vacuum packaging machine is a highly efficient, reliable commercial fully automated packaging solution. Its alternating dual-chamber operation design is specifically engineered to meet the demands of medium to large-scale production for product freshness preservation, oxidation prevention, moisture protection, and extended shelf life.

Its core advantage lies in achieving efficient material sealing through intelligent control and precision mechanical structures. It addresses preservation, freshness retention, and oxidation prevention for food, pharmaceuticals, and industrial products while reducing unit packaging costs by optimizing operational workflows.

- Sealing Efficiency: 15-20 packs/minute

- Heating System: Symmetrical heating strip design, temperature deviation ±2℃

Working Principle

- Loading and Closing: The operator places the bag opening containing the product onto the heat sealing strip of the vacuum chamber tray and closes the vacuum lid.

- Vacuum Extraction: The vacuum pump activates, rapidly removing air from the vacuum chamber and inside the bag to achieve the preset vacuum level (e.g., ≤100mbar).

- Heat Sealing: Following vacuum extraction or inert gas filling, nickel-chromium alloy heating strips instantly heat the packaging film. Precise temperature and time control ensure reliable sealing.

- Cooling and Exhaust: Upon sealing completion, the cooling system rapidly lowers temperature to set the seal.

- Alternating Operations: The vacuum chamber exhausts and depressurizes, automatically unlocking the vacuum lid. Simultaneously, the other vacuum chamber can begin processing the next batch.

Technical parameters

| Model | 400 | 500 | 600 | 700 | 800 |

| Sealing strip spacing | 330mm | 380mm | 430mm | 560mm | 660mm |

| Vacuum chamber size | 520x540x105mm | 620x580x100mm | 720×620*160mm | 820x680x100mm | 920x780x100mm |

| Effective sealing size | 400mm | 500mm | 600mm | 700mm | 800mm |

| Power | 1.0KW | 2.0KW | 3.0KW | 3.0KW | 3.0KW |

| Production efficiency | 180-300/h | 180-300/h | 180-300/h | 120-300/h | 120-300/h |

| Sealing line width (mm) | 10(8) | 10(8) | 10(8)x2/10(8)x4 | 10(8)x2/10(8)x4 | 10(8)x2/10(8)x4 |

| Overall dimensions | 1210x660x900mm | 1320x720x900mm | 1420x750x950mm | 1620x810x970mm | 1820x900x1000mm |

| Rated voltage | 380V/50Hz | ||||

| Total weight | 80kg | 330kg | 360kg | 390kg | 420kg |

Structural Composition

- Control System: Integrated microcomputer intelligent control panel with strong anti-interference capability, enabling precise setting and storage of parameters such as vacuum level, heat sealing time, and temperature.

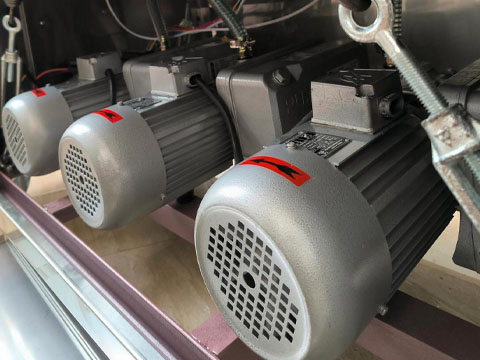

- Vacuum Pump: Serving as the equipment’s “heart,” this rigorously inspected industrial-grade vacuum pump (imported brands available as optional) delivers stable, high-efficiency pumping capacity (e.g., 20m³/h or higher).

- Ergonomic Hinge: Specially designed vacuum lid hinge mechanism significantly reduces operator fatigue, enabling effortless opening and closing for extended continuous operation.

- Durable Main Body Material: The entire main structure is crafted from 304 stainless steel, ensuring a sleek, professional appearance while offering exceptional corrosion resistance for long-term use in harsh production environments.

- V-Shaped Sealing Strip: The V-shaped vacuum chamber sealing strip is made from high-density, pressure-resistant, and wear-resistant material. It provides strong sealing performance and extended service life, reducing replacement frequency and production costs.

- Mobility and Support: Equipped with heavy-duty casters featuring brakes for easy positioning and secure anchoring, ensuring operational stability.

Key Maintenance Points

- Before Daily Operation: Inspect the vacuum pump oil level indicator window to ensure oil is within the standard range, preventing operation with insufficient oil.

- Quarterly Maintenance: Replace the exhaust filter to maintain vacuum efficiency and equipment cooling.

- Annual Deep Maintenance: Replace the oil filter, perform a comprehensive inspection of the vacuum pump, and thoroughly check the wear condition of the V-shaped seal.

- Environmental Requirements: Operate within a clean workshop environment with temperatures controlled between 5-40°C and relative humidity ≤80%.

Features of Double-Chamber Vacuum Packaging Machine

- High-Efficiency Continuous Production: Dual-chamber alternating operation design boosts operational efficiency by approximately 40% for small-to-medium production lines compared to single-chamber equipment, achieving typical packaging speeds of 15-20 packages per minute.

- Intelligent Stable Control: Microcomputer PLC control system + visual interface allows adjustable parameters like time and temperature, ensuring simple operation and stable, reliable performance.

- Durable and Hygienic: Primary structure and contact surfaces utilize food-grade 304 stainless steel, offering corrosion resistance, easy cleaning, and compliance with food and pharmaceutical hygiene standards.

- High Adaptability: Offers multiple vacuum chamber sizes from small (e.g., 300×400mm) to large (e.g., 800×1000mm). We recommend reserving 20% space based on product specifications to accommodate packaging of various product sizes.

Applications of Double-Chamber Vacuum Packaging Machine

- Food Industry: Preserving agricultural products like dates and walnut kernels; sealing granular/bulk foods such as meat products, pickles, seaweed products, and yeast.

- Medical & Health Industry: Sterile sealing of medical devices, pharmaceutical raw materials, traditional Chinese medicine slices, and chemical reagents.

- Industrial Sector: Anti-oxidation and moisture-proof packaging for electronic components and hardware fittings.

- Other Applications: Packaging of chemical raw materials, condiments, local specialties, aquatic products, and seafood.

Why Choose Us?

- Precision Packaging: Rapid vacuum extraction with stable vacuum fluctuations within ±1.8%, compliant heat seal strength, and 99.6% packaging pass rate in medical device applications.

- Cost-Efficiency Optimization: Reduces overall per-unit packaging costs through streamlined processes, low-failure-rate design, and maintenance-friendly structure.

- Full-range solutions: Beyond dual-chamber vacuum packaging machines, we offer diverse food packaging machinery and tailor customized packaging solutions based on your product characteristics.

Our core machine classifications

- Dual-chamber type: Two vacuum chambers operate alternately.

- Continuous type: Continuous operation suitable for medium production capacity.

- Fully automatic bag-feeding type: Integrates weighing, filling, vacuuming, and sealing into one process.

Wanzhi Machinery, a subsidiary of Wanzhi Steel Group, boasts over 14 years of production and export experience. We maintain a complete supply chain and hold multiple certifications including ISO 9001 and CE. If you are interested in packaging machinery, please contact us for more details.

Related Products

Rib/Frozen Meat Slicer

Rib/Frozen Meat Slicer Introduction The Commercial Electric Rib/Frozen Meat Slicer is a CNC fully automatic…

Large Rib Cutting Machine

Large Rib Cutting Machine Introduction As a core piece of equipment in commercial meat processing,…

Commercial Single-Head Multi-Function Vegetable Cutter

Commercial Single-Head Multi-Function Vegetable Cutter Multi-functional vegetable cutter Introduction This product is a single-head multi-function…

Tanzanian Customer Purchases One Oil Press Machine

Tanzanian Customer Purchases One Oil Press Machine production completed Procurement Overview Product Name: Small Commercial…

Small Horizontal Oil Press Machine

Small Horizontal Oil Press Machine Small horizontal oil press Introduction This compact electric horizontal oil…

Contact Us