Dual-speed Meatball Forming Machine

Introduction

The WZ-702 Dual-Speed Meatball Former is engineered for efficient, standardized production of various meatballs, serving as a fully automated forming solution tailored for meat processing applications. Its core advantage lies in dual motor drive paired with a dual variable-frequency speed control system, enabling seamless switching between “high-volume production” and “precision crafting” modes.

Constructed with food-grade stainless steel and durable copper molds, it ensures hygienic production, stable reliability, and easy maintenance. This machine empowers cafeterias, commercial kitchens, and food processing plants to achieve scalable and standardized meatball production.

Working Principle

- This machine employs a precision mechanical principle featuring dual motors operating independently yet in coordination. One motor controls the feeding speed of the screw auger, while the other independently regulates the cutting frequency of the forming blade.

- Through two variable frequency drives enabling stepless speed regulation for each motor, operators can independently and precisely adjust both the “filling extrusion speed” and the “meatball cutting and forming speed.”

- In high-speed mode, both systems operate at high speeds in coordination to achieve rapid, large-scale production. In low-speed mode, the extrusion and cutting actions become gentler, ensuring the filling is not overly compressed or damaged, resulting in meatballs that are denser and more uniformly rounded.

Technical parameters

| Model | WZ-702 Dual-Speed Meatball Forming Machine |

| Voltage | 220/380V |

| Power | 1.3kw |

| Processing Capacity | 80-500 meatballs/min |

| Machine Weight | Approximately 170kg |

| Dimensions | 850X480X1550mm |

| Product Features | Commercial vertical unit |

| Product Uses | Making meatballs, chicken meatballs, fish balls, etc. |

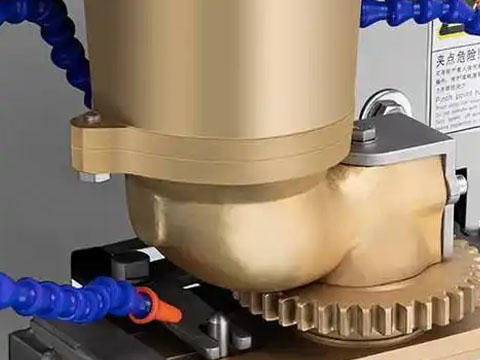

Structural Components

- Dual Motor Dual Frequency System: The core power unit delivers independently adjustable filling and cutting forces, enabling true dual-speed stepless regulation.

- All-Stainless Steel Body and Hopper: Meets food hygiene standards, resists corrosion, and facilitates thorough cleaning.

- Feed Auger: Located inside the hopper, this food-grade stainless steel component uniformly and continuously pushes filling toward the forming end during rotation while allowing easy disassembly for cleaning.

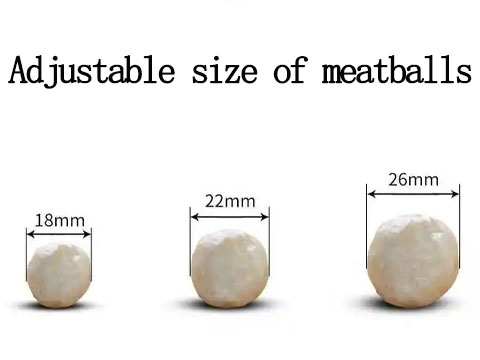

- Solid Copper Forming Die: The critical shaping component, crafted from durable copper that resists oxidation and offers excellent thermal conductivity. Available in multiple diameters (e.g., 10-34mm) to determine the final size of the meatballs.

- Precision Cutting Mechanism: Works in tandem with the die to slice extruded strips of filling into individual meatballs.

- Control Panel: Integrates speed adjustment switches, output control, and a safety anti-leakage switch for intuitive and straightforward operation.

Product Advantages

- Dual-Speed Flexible Control: The unique dual-speed adjustable function enables both high-speed operation to meet daily bulk order demands and low-speed precision processing to enhance premium product quality, offering extensive applicability.

- Consistent Quality: Mechanical forming ensures uniform size and weight of meatballs with excellent roundness and attractive appearance, facilitating product standardization.

- High-Efficiency Production: Automated processes replace extensive manual labor, significantly boosting output per unit time while reducing production costs.

- Durable and Long-Lasting: Key contact parts are constructed from food-grade stainless steel and wear-resistant copper. The machine body is easy to disassemble and clean, featuring low failure rates and extended service life.

- Simple Adjustment: Fine-tune speed and output effortlessly via the inverter control panel—no complex training required.

Application Scenarios and Core Uses

Application Scenarios

Widely applicable across various scenarios in the food processing industry, including small-to-medium-sized food processing plants, chain restaurant central kitchens, school/corporate cafeterias, specialty meatball workshops, etc. It accommodates both large-scale production for bulk supply and small-batch, multi-category customized processing needs.

Core Uses

Capable of producing a diverse range of meatballs, including meat varieties (pork, beef, chicken, etc.), seafood varieties (fish, squid, shrimp, etc.), and specialty varieties (Gongwan, cashew meatballs, etc.). Also compatible with vegetable and tofu-based options. By swapping molds and adjusting speeds, it achieves “one machine, multiple uses,” significantly boosting equipment utilization.

Related Supporting Equipment

To establish a complete meatball processing line, the WZ-702 Dual-Speed Meatball Forming Machine can be integrated with the following equipment to enhance overall production efficiency:

- Raw Material Pre-processing Equipment: Meat grinder, used to grind meat.

- Shaping and Cooking Equipment: Smart temperature-controlled water-boiling tank, enabling integrated shaping and cooking of meatballs.

- Packaging and Storage Equipment: Vacuum packaging machine, used for vacuum sealing finished meatballs.

Usage and Maintenance Key Points

- Before Use: Inspect all component connections for tightness. Clean the machine thoroughly to ensure no residue remains. Install the corresponding mold according to product specifications.

- During Operation: Begin with a low-speed trial run. Adjust to the optimal filling and cutting speed before commencing full production. Feed materials evenly to prevent foreign objects from entering.

- Maintenance: After daily production, disconnect power. Thoroughly disassemble and clean components including the hopper, auger, and molds, then dry them completely. Regularly inspect all fasteners for looseness and lubricate transmission parts as needed. Apply rust prevention measures during extended downtime.

Why Choose Us?

- With over 14 years of production and export experience, we have successfully exported to more than 120 countries and built a large base of loyal customers.

- We offer customized products tailored to client requirements, backed by extensive manufacturing expertise and the use of premium raw materials, ensuring consistent product performance.

- We hold multiple certifications including ISO 9001, CE, and Integrity Supplier. You may view our certificates.

Wanzhi Machinery is a leading Chinese manufacturer of food processing machinery, consistently operating with integrity as our core principle. Our products serve global customers. Should you have any requirements for food-related machinery, please feel free to contact us. We will certainly develop a solution tailored to your needs.

Related Products

Multi Vegetable Cutter

Multi Vegetable Cutter Multi-functional vegetable cutter Introduction This commercial dual-head multi-function vegetable cutter is a…

Commercial Dual-Inverter Vegetable Cutter

Commercial Dual-Inverter Vegetable Cutter Commercial Dual-Inverter Vegetable Cutter Introduction This commercial dual-inverter automatic vegetable cutter…

Commercial Meatball Forming Machine

Commercial Meatball Forming Machine Introduction Wanzhi Machinery’s WZ-605/605S compact commercial fully automatic meatball forming machine…

Potato Peeler Machine

Commercial Potato Peeler Introduction This commercial potato peeler is specifically designed for efficient and hygienic…

Industrial Fruit Vegetable Bubble Washer

Industrial Fruit and Vegetable Bubble Washer Introduction This fruit and vegetable bubble washer, also known…

Contact Us