Vortex Bubble Fruit and Vegetable Washer

Introduction

The vortex bubble washer is a high-efficiency commercial cleaning device that combines physical scrubbing with ozone purification. Specifically designed for deep surface cleaning of various fruits, vegetables, ingredients, and packaged foods, it removes physical contaminants while effectively degrading pesticide residues and achieving sterilization and disinfection. This ensures food safety and extends shelf life.

With its compact size, the vortex bubble washer is ideal for commercial settings such as school cafeterias, chain restaurants, central kitchens, fresh produce supermarkets, and cafes.

Working Principle

The vortex-type fruit and vegetable washer achieves efficient cleaning through the synergistic effect of “ozone oxidation + vortex spray.” The cleaning process is as follows:

- Ozone Water Generation: An ozone generator at the base produces ozone, which is pumped into the wash tank water via a dedicated air pump, rapidly dissolving to form highly oxidizing ozone water.

- Vortex Bubble Impact: High-pressure water flow at the tank bottom interacts with the bubble generator to create dense, rising vortex currents and fine bubbles. Bubbles burst upon contact with produce, releasing energy to create gentle impact and scrubbing action.

- Dual Cleaning Process: Produce continuously tumbles within the circulating water flow. Physically, the vortex and bubbles strip away surface dirt, debris, and other physical contaminants. Simultaneously, ozonated water oxidatively decomposes surfaces, effectively eliminating bacteria and viruses while degrading most pesticide residues like organophosphates.

Technical parameters

| Product Name | Vortex bubble cleaning machine | |||||

| Model | WZZN-XXQP800B | WZZN-XXQP1000B | WZZN-XXQP1200B | WZZN-XXQP1500B | WZZN-XXQP1800B | WZZN-XXQP2000B |

| Voltage | 220V | |||||

| Motor Efficiency | 0.25kw | 0.25kw | 0.37kw | 0.37kw | 0.55kw | 0.75kw |

| Total Power | 3.25kw | 3.25kw | 3.37kw | 3.37kw | 3.55kw | 3.75kw |

| Vegetable Washing Capacity | 100kg/h | 150kg/h | 200kg/h | 260kg/h | 280kg/h | 300kg/h |

| Number of Hair Washed | 10 | 14 | 18 | 22 | 26 | 30 |

| Dimensions | 800X800X950mm | 1000X800X950mm | 1200X800X950mm | 1500X800X950mm | 1800X800X950mm | 2000X800X950mm |

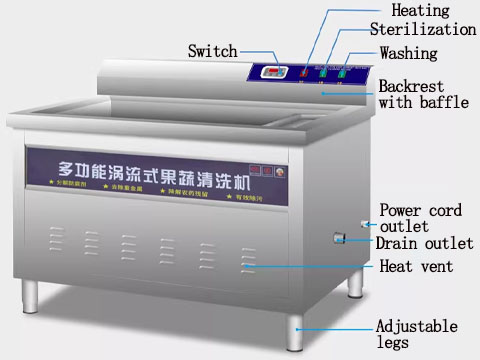

Primary Structural Components

- Washing Tank: The main working area, constructed from food-grade stainless steel, designed to hold materials awaiting cleaning and washing water.

- Filter Tank: Typically positioned on one side of the equipment, featuring multiple internal baffles and activated carbon filter layers. It intercepts and settles silt, hair, and fine impurities generated during washing, achieving preliminary purification.

- Circulation Pump: Provides core power for system water circulation, pumping filtered water back into the washing tank to create continuous vortex flow.

- Vortex Generator: Located at the tank bottom, synchronized with the pump, it generates tumbling vortex flow through specialized water flow design.

- Ozone Generator System: Integrates an ozone generator and air pump to inject ozone into the water during washing, achieving sterilization and pesticide residue degradation.

- Drain Valve: Rapidly empties wastewater from the tank after cleaning.

- Electrical Control System: Includes power switch and leakage protector for operational safety and simplified control.

Advantages of Vortex Bubble Fruit and Vegetable Washer

- High Cleaning Efficiency: Ozonated water thoroughly removes surface residues from produce, while vortex spraying effectively strips away physical contaminants for superior cleaning.

- Exceptional Sterilization and Pesticide Removal: Ozone’s potent oxidizing power eliminates most harmful microorganisms on produce surfaces while breaking down pesticide residues.

- User-Friendly Operation: The intuitive control panel features adjustable functions and supports one-touch automated cleaning cycles, significantly lowering operational barriers and labor costs.

- Economical and Hygienic Operation: Equipment typically supports filtered water recirculation (using activated carbon adsorption), conserving water resources. All-stainless steel construction and streamlined design facilitate thorough cleaning and maintenance.

What Products Can Be Packaged

- Suitable Materials: Covers leafy vegetables (lettuce, Chinese cabbage, pickled vegetables, black fungus, sea vegetables, etc.), various fruits, poultry, seafood, soy products, and other root/bulb vegetables. Also accommodates cleaning needs for materials with food packaging.

- Suitable Scenarios: Ingredient pre-processing in central kitchens and group meal distribution centers; supermarket fresh produce sections, pre-washed vegetable processing plants, fruit distribution centers, small food processing plants, institutional cafeterias (schools/hospitals/corporate cafeterias).

Instructions for Use

- Equipment Placement: Position the washer steadily on a solid, level surface, ensuring it is stable without wobbling and has drainage access. Connect the power cord to a ground fault circuit interrupter (GFCI) to ensure electrical safety.

- Water Preparation: Fill the unit with clean water to a level that just submerges the right-side filter tank. Avoid excessive or insufficient water levels, which may impair cleaning and filtration efficiency.

- Material Cleaning: Distribute materials evenly into the cleaning tank. Activate the circulating water and ozone pump to generate vigorous turbulent currents that agitate and cleanse the materials.

- Final Steps: After cleaning, turn off the power switch. Open the drain valve to completely empty the wastewater from the tank for subsequent cleaning and storage.

Why Choose Us?

- Rigorous Attention to Detail: All products are covered with specialized protective film before shipment, effectively preventing surface scratches during transportation, storage, and installation to ensure pristine equipment appearance.

- Safe and Reliable Packaging: Utilizing exquisite and secure custom packaging that comprehensively addresses cushioning, moisture resistance, and stabilization, minimizing damage risks during transit.

- Integrity-Driven Enterprise: With over 14 years of manufacturing and export experience, our company holds multiple certifications including ISO 9001, ISO 14001, and CE, operating as a trustworthy business.

Wanzhi Machinery is a leading supplier of food-related machinery in China, offering products such as fruit and vegetable washers, extractors, processing machines, and various stainless steel tanks. Deeply rooted in the food machinery industry, we welcome inquiries for any related equipment.

Related Products

Commercial Single-Head Multi-Function Vegetable Cutter

Commercial Single-Head Multi-Function Vegetable Cutter Multi-functional vegetable cutter Introduction This product is a single-head multi-function…

Multi Vegetable Cutter

Multi Vegetable Cutter Multi-functional vegetable cutter Introduction This commercial dual-head multi-function vegetable cutter is a…

Commercial Dual-Inverter Vegetable Cutter

Commercial Dual-Inverter Vegetable Cutter Commercial Dual-Inverter Vegetable Cutter Introduction This commercial dual-inverter automatic vegetable cutter…

Potato Peeler Machine

Commercial Potato Peeler Introduction This commercial potato peeler is specifically designed for efficient and hygienic…

Industrial Fruit Vegetable Bubble Washer

Industrial Fruit and Vegetable Bubble Washer Introduction This fruit and vegetable bubble washer, also known…

Contact Us