Industrial Fruit and Vegetable Bubble Washer

Introduction

This fruit and vegetable bubble washer, also known as a mesh belt bubble washer, serves as the core pre-treatment equipment in modern fruit and vegetable processing lines (such as tomato paste production lines and fresh-cut production lines).

WIt integrates bubble tumbling, high-pressure spraying, and automated conveying technology, specifically designed for efficient, thorough, and gentle cleaning of diverse agricultural products. The equipment significantly enhances cleaning purity and production efficiency while offering notable water-saving capabilities and low damage rates. It is widely applicable across multiple industries including food processing, Chinese herbal medicine, and seafood purification.

Working Principle

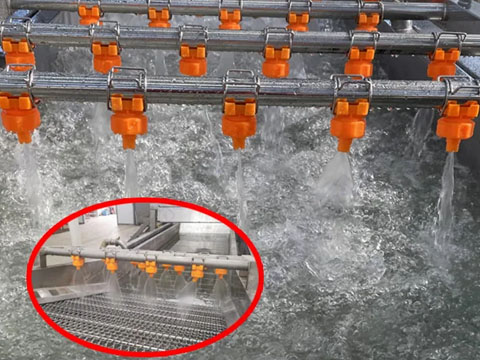

- Bubble Tumbling Wash: Materials enter a wash tank filled with an appropriate amount of water. A bubble generator at the bottom produces dense bubbles. As these bubbles rise and burst, the resulting impact force causes the materials to tumble thoroughly in the water and rub against each other. This effectively separates surface-adhering mud, impurities, and some pesticide residues.

- Mesh Belt Conveying: While tumbling under bubble action, materials are carried by a corrosion-resistant stainless steel mesh belt. The belt moves forward at an adjustable, steady speed, ensuring uniform and controllable cleaning duration.

- High-Pressure Spray Rinsing: As materials emerge from the water surface, they pass through multiple high-pressure spray nozzles positioned above for a final deep rinse. This thoroughly removes residual contaminants and any cleaning agents used, completing the entire process from initial washing to final rinsing. Water temperature is adjustable via built-in heating elements to accommodate diverse material cleaning requirements.

Technical parameters

| Model | WZ-XCJ300B | WZ-XCJ400B | WZ-XCJ500B | WZ-XCJ600B | |

| Voltage | 380V/50Hz | ||||

| Total Power | 2.25kw | 3kw | 3.75kw | 5.25kw | |

| Conveying Speed | Manual speed adjustment | ||||

| Belt (Chain) Width | 600mm | 600mm | 800mm | 800mm | |

| Square Tube | 50*50*1.5mm | 50*50*1.5mm | 50*50*1.5mm | 50*50*1.5mm | |

| Dimensions (including external water tank) | 3100*1450*1400mm | 4100*1450*1400mm | 5100*1600*1400mm | 6100*1600*1400mm | |

| Type | Fully automatic | ||||

| Application Scope | Various fruits and vegetables, agricultural by-products, and Chinese medicinal herbs | ||||

| Customization Required | Support | ||||

| Processing Capacity | 300-2000kg/h | ||||

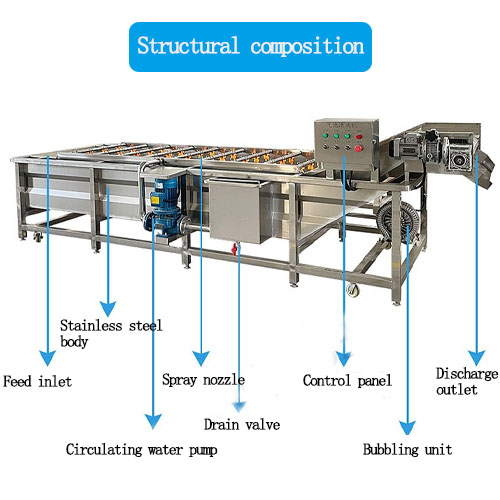

Primary Structural Components

Primary structure includes feed inlet, stainless steel body, recirculating pump, spray nozzles, drain valve, control panel, bubbling assembly, and discharge outlet:

- Main Frame: Constructed with food-grade SUS304 stainless steel frame and housing for corrosion resistance, easy cleaning, and compliance with food safety standards.

- Core Cleaning System: Incorporates a bubble generation unit, high-pressure water pump, and spray piping system. Optional modules include brush rollers and floating debris filtration devices.

- Conveying System: Comprises a stainless steel conveyor belt, variable frequency drive, and speed control mechanism for smooth, adjustable-speed material transport.

- Control System: Features a PLC-based intelligent control panel supporting one-touch start/stop and stepless conveyor speed adjustment for streamlined automation.

Advantages

- High-Efficiency Deep Cleaning: Combines bubble penetration with high-pressure water jets to achieve cleaning levels far surpassing manual methods, with exceptional results in crevices and folds.

- Gentle, Damage-Free Protection: Utilizes the flexible physical force of bubbles for cleaning, significantly reducing material damage rates.

- Smart Water-Saving and Labor-Saving: Closed-loop water circulation design and efficient cleaning processes conserve substantial water usage; Fully automated operation substantially reduces labor intensity and saves on personnel costs.

- Robust, Stable, and Durable: Premium stainless steel construction and sturdy structural design ensure long-term stable operation in humid environments, offering extended lifespan and easy maintenance.

- Flexible Customization: Conveyor speed, cleaning section length, and additional functions (e.g., brushes, heating, filtration) can be tailored to specific customer process requirements, enabling multi-purpose use.

Commercial Potato Peeler Applications

- Fruits & Vegetables: Leafy greens, berries (strawberries, blueberries, etc.), root vegetables (radishes, potatoes, etc.), and various melons and fruits.

- Herbal Medicines: Root and fruit-based medicinal materials requiring cleaning and impurity removal (ginseng, goji berries, etc.).

- Seafood & Aquatic Products: Shellfish (clams, scallops), squid, fish, shrimp, etc. Effectively removes sand and mucus.

- Meat & Poultry: Initial surface cleaning for chicken, chicken/duck gizzards, pig trotters, etc.

- Others: Mushrooms, grains, and legumes.

Why Choose Us?

- Exceptional Cleaning Performance: Combines bubble action with spray rinsing to ensure thorough cleaning while preventing surface damage.

- Safe and Reliable Materials: SUS304 stainless steel construction meets food production hygiene standards, offering corrosion resistance and easy maintenance.

- Stable and Efficient Operation: Variable frequency speed control and automated systems ensure continuous, smooth operation, suitable for large-scale production demands.

- Cost-Effective: Significantly reduces labor and water consumption while boosting processing efficiency and product yield, delivering high ROI.

- Versatile Adaptability: Customizable functional modules (e.g., brushes, filters) tailored to production line needs enable multi-purpose operation.

Wanzhi Machinery is a professional supplier of fruit and vegetable processing equipment, offering a wide range of machinery including fruit and vegetable washers, fruit and vegetable pulpers, multi-functional vegetable cutters, peelers, and destoners. We provide one-stop procurement solutions to meet all your needs. For any inquiries, please feel free to contact us anytime.

Related Products

Commercial Single-Head Multi-Function Vegetable Cutter

Commercial Single-Head Multi-Function Vegetable Cutter Multi-functional vegetable cutter Introduction This product is a single-head multi-function…

Multi Vegetable Cutter

Multi Vegetable Cutter Multi-functional vegetable cutter Introduction This commercial dual-head multi-function vegetable cutter is a…

Commercial Dual-Inverter Vegetable Cutter

Commercial Dual-Inverter Vegetable Cutter Commercial Dual-Inverter Vegetable Cutter Introduction This commercial dual-inverter automatic vegetable cutter…

Potato Peeler Machine

Commercial Potato Peeler Introduction This commercial potato peeler is specifically designed for efficient and hygienic…

Vortex Bubble Fruit and Vegetable Washer

Vortex Bubble Fruit and Vegetable Washer Introduction The vortex bubble washer is a high-efficiency commercial…

Contact Us