Commercial Potato Peeler

Introduction

This commercial potato peeler is specifically designed for efficient and hygienic ingredient pre-processing. Its all-stainless steel construction ensures both durability and easy cleaning.

The machine achieves high-efficiency peeling through replaceable sand plate technology, making it widely applicable for processing potatoes and similarly shaped fruits and vegetables. It is an ideal choice for cafeterias, central kitchens, and food processing enterprises.

Working Principle

This machine employs the core principle of physical friction peeling for efficient results. Upon activation, ingredients enter the processing drum where the core working components—the abrasive plates lining the drum interior and the feed tray—create relative motion with the produce. The rough surface of the abrasive plates generates friction against the outer skin, precisely and rapidly stripping away the potato peel.

Simultaneously, the inner walls feature a specially reinforced design that prevents potato skins from adhering during friction. Combined with the washing process, this allows the peeled ingredients, potato skins, and wastewater to separate naturally. This ensures uniform peeling results while facilitating subsequent cleaning operations.

Technical parameters

| Model | PP8 | PP15 | PP30 |

| Voltage | 220V | 220V | 220V |

| Motor Power | 0.37kw | 0.75kw | 1.5kw |

| Capacity | 8kg | 15kg | 30kg |

| Weight | 52kg | 66kg | 87kg |

| Dimensions | 480X480X780 | 500X500X860 | 590X530X1030 |

| Model | PP350 | PP450 |

| Voltage | 220V | 220V |

| Motor Power | 1.5kw | 1.5kw |

| Capacity | 45kg | 45kg |

| Weight | 110kg | 110kg |

| Dimensions | 750X510X830 | 750X550X950 |

Structural Components

- All-stainless steel body: Corrosion-resistant, easy to clean, meets food processing hygiene standards.

- Replaceable sanding plate system: Modular sanding plates for inner drum walls and discharge trays enable quick replacement.

- Reinforced Drain Pipe Design: Compatible with waste water buckets for smooth drainage and easy cleanup.

- Side-Opening Leak-Proof Discharge Port: Large-diameter design ensures safe, rapid discharge and prevents clogging.

- Enclosed Drive Structure: Sealed protection for bearings and transmission components, suitable for humid and hot working environments.

Commercial Potato Peeler Features

- Reliable Quality, Hygienic Compliance: Fully stainless steel construction ensures both aesthetic appeal and durability, effortlessly meeting the frequent cleaning demands of commercial settings.

- Easy maintenance, controlled costs: Core sanding plate is removable and replaceable without complex procedures, significantly reducing long-term repair costs and downtime for maintenance.

- Efficient, labor-saving, increased output: Processes large volumes per minute with notable efficiency gains, meeting bulk ingredient processing needs while saving labor costs.

- Precise peeling, intact ingredients: Peeling process preserves fruit/vegetable integrity without damaging flesh, minimizing raw material waste.

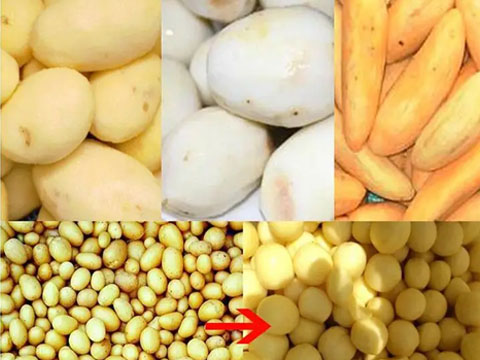

- Multi-functional versatility: Beyond potatoes, it efficiently peels various round or oval vegetables like sweet potatoes, radishes, and ginger.

Application Scope

- Core Application Scenarios: Widely compatible with various commercial settings requiring bulk ingredient processing, including school/corporate/hospital cafeterias, chain restaurant kitchens, central kitchens, food processing plants, fruit and vegetable deep-processing enterprises, and snack food factories.

- Scope of Application: Covers a wide range of root and tuber vegetables. Primarily designed for potatoes while also compatible with sweet potatoes, radishes, ginger, and other round or oval-shaped produce. Capable of integrated washing and peeling operations, flexibly meeting diverse needs across different food processing scenarios.

Why Choose Us?

- We have extensive manufacturing and export experience, with a history of over 14 years.

- Our products are highly customizable to meet various customer needs.

- All products are manufactured using high-quality stainless steel, ensuring stable performance and a long service life.

- Our products have passed various certifications, including ISO 9001 and CE certifications.

Wanzhi Machinery is a professional supplier of food processing machinery and equipment, including not only potato peeling machines but also fruit and vegetable washing machines, fruit and vegetable coring machines, vegetable cutting and slicing machines, and more. Please feel free to contact us if you have any requirements.

Related Products

Commercial Single-Head Multi-Function Vegetable Cutter

Commercial Single-Head Multi-Function Vegetable Cutter Multi-functional vegetable cutter Introduction This product is a single-head multi-function…

Multi Vegetable Cutter

Multi Vegetable Cutter Multi-functional vegetable cutter Introduction This commercial dual-head multi-function vegetable cutter is a…

Commercial Dual-Inverter Vegetable Cutter

Commercial Dual-Inverter Vegetable Cutter Commercial Dual-Inverter Vegetable Cutter Introduction This commercial dual-inverter automatic vegetable cutter…

Industrial Fruit Vegetable Bubble Washer

Industrial Fruit and Vegetable Bubble Washer Introduction This fruit and vegetable bubble washer, also known…

Vortex Bubble Fruit and Vegetable Washer

Vortex Bubble Fruit and Vegetable Washer Introduction The vortex bubble washer is a high-efficiency commercial…

Contact Us