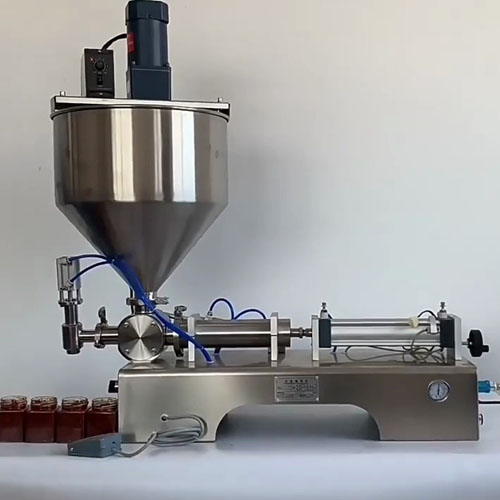

Semi-Automatic Paste Filling Machine

Introduction

The semi-automatic paste filling machine is specifically designed for handling high-viscosity materials such as ketchup, toothpaste, ointments, cosmetics, butter, jam, and adhesives. While manual intervention is required for placing and removing containers, the filling process is fully automated. Its flexibility and cost-effectiveness make it an ideal choice for small and medium-sized enterprises as well as customized production.

Wanzhi Machinery’s semi-automatic paste filling machine features a single-head configuration. Customization for dual-head or quad-head setups is available upon request.

Working Principle

The core principle is “piston metering, pneumatic drive, human-machine coordination.”

- An operator positions an empty container over the filling port and presses the foot switch to activate the equipment;

- The motor agitates the hopper to prevent paste clumping, while the pneumatic cylinder drives the piston. Coordinating with the rotary valve, it first draws a preset volume of paste from the hopper;

- After the rotary valve switches direction, the piston forces the paste through the filling nozzle into the container. Upon completion, the operator removes the filled bottle, initiating the next cycle.

Technical Parameters

| Model | WZ-100 | WZ-300 | WZ-500 | WZ-1000 | WZ-2000 | WZ-3000 | WZ-5000 |

| Filling Range | 5-120ML | 20-330ML | 30-550ML | 80-1100ML | 200-2300ML | 350-3100ML | 800-5300ML |

| Optimal Filling Range | 10-100ML | 30-300ML | 50-500ML | 100-1000ML | 300-2000ML | 500-2800ML | 1000-5000ML |

| Voltage | 220V+ 5V 110V ±5V | ||||||

| Current | 1A | ||||||

| Power | 50W | ||||||

| Air Pressure | 0.4-0.9MPa | ||||||

| Filling Speed | Single head 10-30 bottles/min | ||||||

| Air Volume | ≥0.1m³/min | ||||||

| Filling Accuracy | ≤+1% | ||||||

| Number of Filling Heads | 1 head (2 or 4 heads available upon request) | ||||||

| Stirring Power | 120-370W | ||||||

| Working Principle | Electrical combination (pneumatic filling, electric mixing tank) | ||||||

| Dimensions (excluding hopper) | 950*320*280mm | 1150*320*350mm | 1150*320*350mm | 1150*320*350mm | 1230*370*380 | 1270*400*370mm | 1330*400*430mm |

| Net Weight | 35-55KG | ||||||

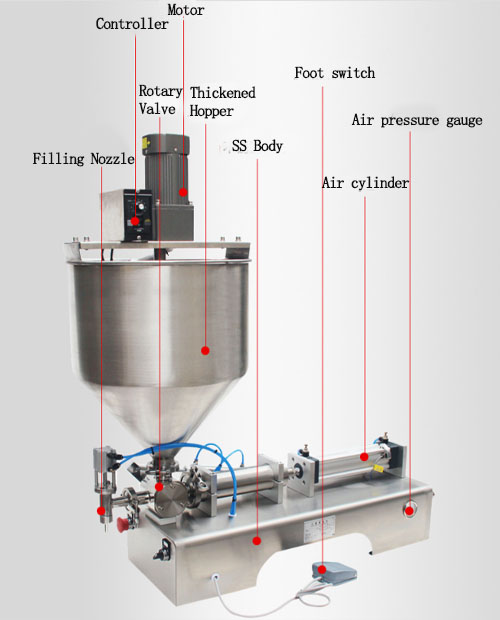

Structural Components

- Motor: Serves as the power source for the equipment, providing driving force for the reciprocating motion of the piston or the conveying system.

- Agitator Control Unit: Adjusts the rotational speed of the mixing tank.

- Filling Outlet: The final passageway for material discharge.

- Rotary Valve: A critical directional control component. It switches the flow direction of materials through rotation.

- Thickened Hopper: Stores paste-like materials awaiting filling.

- Stainless Steel Body: Forms the main structure and external protection of the equipment.

- Foot Switch: Manually triggers the filling action.

- Air Cylinder: The actuator driving the piston for suction and filling operations.

- Air Pressure Gauge: Monitors and displays the pressure value of the compressed air system.

Fillable Materials

- Food Products: Ketchup, mayonnaise, honey, jam, butter, sesame paste, hot pot bases, thick fillings.

- Cosmetics: Face cream, lotion, mask paste, shampoo, conditioner, toothpaste, essence, hair wax.

- Pharmaceuticals & Chemicals: Ointments, creams, disinfectant gel, adhesives, lubricants, sealants, ink, coatings.

Related Products

Multi Vegetable Cutter

Multi Vegetable Cutter Multi-functional vegetable cutter Introduction This commercial dual-head multi-function vegetable cutter is a…

Commercial Dual-Inverter Vegetable Cutter

Commercial Dual-Inverter Vegetable Cutter Commercial Dual-Inverter Vegetable Cutter Introduction This commercial dual-inverter automatic vegetable cutter…

Dual-speed Meatball Forming Machine

Dual-speed Meatball Forming Machine High-speed meatball forming machine Introduction The WZ-702 Dual-Speed Meatball Former is…

Commercial Meatball Forming Machine

Commercial Meatball Forming Machine Introduction Wanzhi Machinery’s WZ-605/605S compact commercial fully automatic meatball forming machine…

Potato Peeler Machine

Commercial Potato Peeler Introduction This commercial potato peeler is specifically designed for efficient and hygienic…

Contact Us