Stainless Steel Spherical Evaporator

Introduction

The stainless steel spherical evaporator, also known as a spherical concentrator, has become a core piece of equipment in concentration, distillation, and solvent recovery processes thanks to its vacuum concentration technology. It not only delivers high efficiency but also excels at preserving the active components of heat-sensitive materials.

Our spherical evaporators are constructed from food-grade stainless steel, featuring mirror-polished inner surfaces and matte-finished outer walls for superior safety, hygiene, and performance. For further details, please contact us.

- Material: 304 or 316L

- Processing Capacity: 0.1 – 0.3 tons

- Capacity: 300L – 2000L

Working Principle

The core operating principle of this stainless steel spherical vacuum evaporator is based on reduced-pressure evaporation (vacuum concentration).

- By creating a vacuum within the system, the boiling point of the liquid in the tank is significantly reduced, enabling the material to boil and evaporate at relatively low temperatures.

- The vapor-liquid mixture generated by the evaporation of the heated material enters the tubular condenser through piping, where it is rapidly cooled and condensed.

- During this process, the gas-liquid separator precisely separates the uncondensed gas from the liquid. The liquid component flows into the receiving tank for collection, while the non-condensable gases are vented through the vacuum system.

Technical parameters

| Specifications/Model | WZ-300 | WZ-500 | WZ-700 | WZ-1000 | WZ-1500 | WZ-2000 | |

| Evaporation Rate (kg/h) | 70 | 120 | 145 | 195 | 250 | 350 | |

| Volume (L) | 300 | 500 | 700 | 1000 | 1500 | 2000 | |

| Inner Diameter of Sphere (mm) | 800 | 990 | 1115 | 125 | 1400 | 1600 | |

| Steam Pressure (MPa) | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | |

| Jacket Pressure (MPa) | 0.09 | 0.09 | 0.09 | 0.09 | 0.09 | 0.09 | |

| Vacuum Degree (MPa) | -0.05-0.08 | -0.05-0.08 | -0.05-0.08 | -0.05-0.08 | -0.05-0.08 | -0.05-0.08 | |

| Heating Area (㎡) | 1.6 | 2 | 2.3 | 3.2 | 4 | 5.2 | |

| Condensing Area (㎡) | 3.9 | 5 | 5.8 | 8.2 | 11 | 16 | |

| Water Consumption (T/H) | 5 | 5 | 8 | 8 | 10 | 12 | |

| Steam Inlet (mm) | 32 | 32 | 32 | 40 | 40 | 40 | |

| Water Inlet (mm) | 32 | 32 | 40 | 40 | 50 | 50 | |

| Liquid Collection Tank Volume (L) | 150 | 200 | 220 | 240 | 280 | 300 | |

| Electric Heating (KW)/Steam | 24 | 27 | 27 | 36 | Steam | Steam | |

| Equipment Weight | 400 | 500 | 700 | 1000 | 1600 | 1950 | |

| Dimensions | Length (mm) | 1900 | 2030 | 2100 | 2335 | 2500 | 2750 |

| Width (mm) | 1100 | 1200 | 1300 | 1520 | 1700 | 1800 | |

| Height (mm) | 2300 | 2500 | 2600 | 2765 | 2900 | 3100 | |

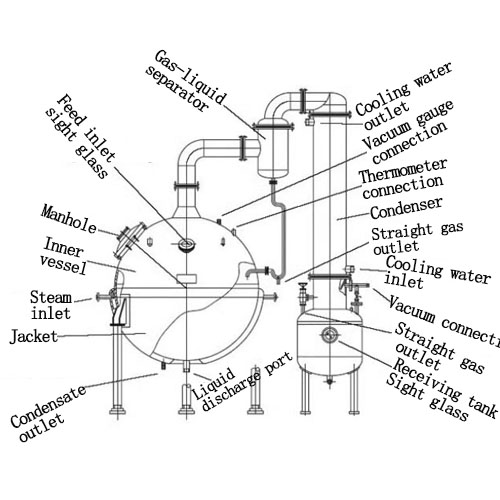

Structural Composition

Core components are constructed from premium 304 or 316L stainless steel to ensure corrosion resistance and hygiene standards for material-contact surfaces:

- Concentration Tank Body: Spherical design maximizes heating surface area and facilitates uniform material mixing. Mirror-polished inner liner minimizes residue buildup and scaling.

- Tube-Type Condenser: Tube-and-shell heat exchange ensures efficient heat dissipation and high condensation efficiency, rapidly converting steam into liquid.

- Gas-Liquid Separator: Precisely separates liquid and gas from steam, enhancing product purity and preventing impurities from affecting quality.

- Cooler and Receiving Tank: The cooler further lowers condensate temperature. The receiving tank (with sight glass) stores the finished product, facilitating level monitoring and discharge operations.

- Auxiliary Function Interfaces: Equipped with feed inlet, manhole, steam inlet, jacket, condensate outlet, cooling water inlet/outlet, vacuum gauge port, thermometer port, and vacuum connection to support feeding, maintenance, and parameter monitoring throughout the entire process.

Applications of Spherical Evaporators

- Pharmaceutical Industry: Concentration of heat-sensitive materials such as Chinese herbal extracts, vitamins, and antibiotics; recovery of pharmaceutical alcohol.

- Food and Beverage Industry: Concentration processing of fruit juices, jams, plant extracts, condiments, honey, etc., and purification of alcoholic beverages.

- Light Industry and Chemical Industry: Recovery of organic solvents, concentration of dilute solutions, purification of chemical intermediates, concentration of health supplement extracts, purification of cosmetic raw materials, etc.

Spherical Concentrator Tank Product Advantages

- High Efficiency & Energy Savings: Spherical structure optimizes heat transfer, while vacuum pressure reduction technology significantly lowers boiling point of materials, shortening concentration time, reducing energy consumption, and boosting production capacity.

- Protection of Heat-Sensitive Components: Low-temperature concentration process prevents degradation of active ingredients in heat-sensitive materials, making it particularly suitable for industries demanding high component retention, such as pharmaceuticals and food processing.

- Premium Materials: Constructed from SUS304/316L stainless steel with mirror-polished inner walls and matte exterior finish. Ensures hygienic safety, complies with GMP standards, and offers durable, easy-to-clean performance.

- Flexible Adaptability: Precisely controls concentration rate, final product concentration, and alcohol recovery purity by adjusting vacuum level, temperature, and reflux ratio, accommodating diverse process requirements.

Why Choose Us?

- We are a professional manufacturer of stainless steel tank products, with extensive expertise in extraction and concentration equipment.

- Employing rigorous manufacturing processes, all components in contact with materials are crafted from premium stainless steel, ensuring long-lasting durability and stable operation.

- We offer material options in SUS304/SUS316L, with processing capacities adaptable to your needs. Equipment can be customized to align with your specific process parameters.

Wanzhi Machinery is China’s leading supplier of extraction equipment. As a certified supplier holding ISO 9001, ISO 14001, and CE certifications, we provide comprehensive professional technical support and services from equipment selection to post-installation maintenance. We are your trusted long-term partner.

Related Products

Extraction and Concentration Unit

Heat Reflux Extraction and Concentration Unit Introduction The Thermal Reflux Extraction and Concentration Unit is…

Plant Oil Extractor

Plant Oil Extractor Introduction Plant Oil Extraction Equipment is a modern apparatus specifically designed to…

Small Extraction, Concentration

Small Extraction, Concentration, and Filtration Machine Introduction This highly integrated, comprehensive, multifunctional process equipment integrates…

Honey Concentrator

Honey Concentrator Introduction The honey concentrator is a core piece of equipment in honey processing….

Contact Us