Heat Reflux Extraction and Concentration Unit

Introduction

The Thermal Reflux Extraction and Concentration Unit is a modern integrated extraction and concentration system. Through innovative thermal reflux circulation technology, it seamlessly combines extraction and concentration processes, significantly boosting production efficiency and product yield. It is an ideal choice for organic solvent extraction and the separation and purification of natural products.

Our extraction and concentration units are constructed from premium 304 stainless steel, offering a wide range of capacities to accommodate diverse extraction process requirements.

- Extraction Tank Volume: 500L – 6000L (customizable)

- Concentration Specific Gravity Range: 1.0 – 1.4

- Material: 304/316 Stainless Steel

Working Principle

1. Pre-treatment and Charging: Add crushed herbal materials to the extraction tank and introduce 5-10 times the volume of solvent (water/organic solvent) according to the process specifications.

2. Heating and Boiling Stage: Activate steam in the extraction tank jacket and open the straight-through valve to heat the extract to boiling point (20-30 minutes), initiating dissolution of active components.

3. Circulating Extraction

- Transfer one-third of the extract via suction tube to the concentrator. Shut off the extractor steam supply and activate the heater for concentration.

- The secondary steam generated during concentration is conveyed through the evaporator back to the extractor. It serves as both a heat source to sustain boiling and condenses as hot solvent to reflux over the herb bed.

- The hot solvent rapidly penetrates the herbal layer from top to bottom, maintaining a high concentration gradient between the herbal solute and solvent to achieve complete dissolution of active components.

4. Concentration and Solvent Recovery: After extraction, the secondary steam is diverted to the cooler, while the concentrator continues operation until the target specific gravity (1.2–1.34) is reached.

5. Discharge and residue processing: Residual solvent in the extraction tank can be pumped into storage tanks for reuse in subsequent batches; after organic solvent extraction, the solvent must be recovered before discharging the residue.

Technical parameters

| Product Model | RCN-500 | RCN-1000 | RCN-2000 | RCN-3000 | RCN-6000 |

| Extraction Tank Volume (L) | 500 | 1000 | 2000 | 3000 | 6000 |

| Concentrator Volume (L) | 300 | 500 | 1000 | 1500 | 2500 |

| Feed Rate (kg) | 50-100 | 100-250 | 200-450 | 300-700 | 600-1500 |

| Time (h) | 3 – 6 | 4 – 6 | 5 – 7 | 5 – 8 | 6 – 8 |

| Specific Gravity of Concentration | 1.2-1.35 | 1.2-1.35 | 1.2-1.35 | 1.2-1.35 | 1.2-1.35 |

| Water Extraction Temperature | 90-100℃ | 90-100℃ | 90-100℃ | 90-100℃ | 90-100℃ |

| Alcohol Extraction Temperature | 78-83℃ | 78-83℃ | 78-83℃ | 78-83℃ | 78-83℃ |

| Vacuum Degree | 0.05-0.08Mpa | 0.05-0.08Mpa | 0.05-0.08Mpa | 0.05-0.08Mpa | 0.05-0.08Mpa |

| Operating Pressure | 0.08-0.2Mpa | 0.08-0.2Mpa | 0.08-0.2Mpa | 0.08-0.2Mpa | 0.08-0.2Mpa |

| Dimensions (m) | 2.5*1.5*5.0 | 3.0*2.0*6.0 | 3.0*2.0*8.0 | 4.0*2.8*9.5 | 4.5*3.5*10.0 |

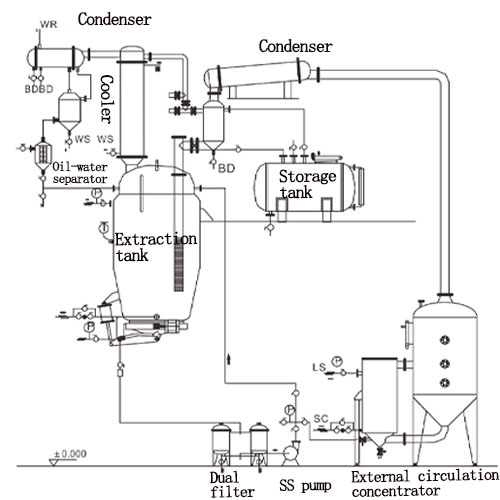

Structural Composition

- Extraction Tank: Main vessel (volume options: 0.5–6 m³), equipped with a jacket heating system, herbal material inlet, solvent inlet, stirring device (optional), and residue discharge door. Internal filtration structure ensures clean extraction liquid.

- Concentrator: Includes evaporation chamber, heater, and separator, responsible for concentrating the extraction liquid and generating secondary steam for the extraction process.

- Condenser: Condenses secondary vapor into liquid solvent, enabling solvent recycling.

- Solvent Recovery System: Recovers and reuses organic solvents, significantly reducing production costs.

- Vacuum Filtration Piping & Circulation Pump: Connects the extraction tank to the concentrator, enabling directed flow of extract within the system.

- Control System: Utilizes PLC or automated instrumentation for precise regulation of temperature, pressure, liquid level, and process flow.

- Storage Tank: Holds recovered solvents or intermediate extraction liquids.

- Cooler: Cools secondary steam during late-stage concentration to ensure safe and stable system operation.

- Auxiliary Components: Deaerator, water collection tank, metering tank, storage tank, and pneumatic residue discharge device.

Heat Reflux Extraction and Concentration Unit Applications

Thermal reflux extraction and concentration units are commonly used in pharmaceuticals, health supplements, food processing, cosmetics, biotechnology, and related industries for the extraction and concentration of the following products:

- Natural product extraction: Separation of active ingredients from herbal plants, traditional Chinese medicinal materials, and animal-derived medicines;

- Solvent recovery and concentration: Recycling of solvents such as water, ethanol, methanol, and acetone;

- Product Preparation: Food additives, natural pigments, health supplement ingredients, etc.

Extractable Plants

- Herbal Medicines: Honeysuckle, Astragalus, Ginseng, Licorice, Ginkgo Leaf, etc.

- Traditional Chinese Medicinal Materials: Various roots, stems, leaves, flowers, fruits, and whole plant materials

- Animal-Derived Medicines: Deer Antler, Scorpion, Centipede, and other animal-sourced medicinal materials

- Food additives: Natural pigments, flavorings, antioxidants, etc.

- Other natural products: Plant essential oils, active ingredients, standardized extracts, etc.

Heat Reflux Extraction and Concentration Unit Advantages

- High-efficiency extraction: From herbal materials to ointment in just 5-8 hours, with equipment utilization increased by over 40%.

- Component enrichment: Ointment yield boosted by 10-15%, active ingredient content doubled, and higher purity of extraction solution.

- Energy Savings & Reduced Consumption: Steam consumption reduced by 50% (through secondary steam heat recovery), solvent usage cut by 30%, and consumption rate lowered by 50-70%.

- Integrated Design: Extraction and concentration occur within the same sealed system, minimizing intermediate steps and contamination risks. Compact equipment footprint.

- Simplified Operation: High automation reduces personnel requirements; closed-loop solvent circulation achieves ≥95% recovery rate with minimal volatilization losses, ensuring safer and more environmentally friendly working conditions.

- Strong Process Adaptability: Suitable for water extraction, alcohol extraction, and various organic solvent extraction methods; accommodates multiple extraction processes including ambient temperature, warm maceration, hot reflux, and percolation.

Why Choose Us?

We are a professional extraction equipment manufacturer in China with over 14 years of production and export experience. Leveraging our extensive expertise, we have earned the trust of loyal customers from numerous countries. Holding certifications including ISO 9001 and CE, we consistently operate with integrity as our core principle. For any extraction equipment needs, please feel free to contact us.

Related Products

Stainless Steel Spherical Evaporator

Stainless Steel Spherical Evaporator Introduction The stainless steel spherical evaporator, also known as a spherical…

Plant Oil Extractor

Plant Oil Extractor Introduction Plant Oil Extraction Equipment is a modern apparatus specifically designed to…

Small Extraction, Concentration

Small Extraction, Concentration, and Filtration Machine Introduction This highly integrated, comprehensive, multifunctional process equipment integrates…

Honey Concentrator

Honey Concentrator Introduction The honey concentrator is a core piece of equipment in honey processing….

Contact Us