Multi Vegetable Cutter

Introduction

This commercial dual-head multi-function vegetable cutter is a high-efficiency kitchen engineering appliance integrating two cutting systems. It innovatively combines a high-speed leaf-cutting system with a precision root-and-stem slicing system within a compact body, achieving a revolutionary breakthrough of “dual functionality in one machine with simultaneous processing.”

Whether handling delicate spinach or cilantro, or tough radishes and potatoes, this machine employs optimized dual-path processing to simultaneously achieve precise cutting into strips, slices, cubes, chunks, and mince in a single operation.

Working Principle

This machine operates on a core logic of “dual-head independent drive + separate feed channels + dual-speed precision control,” achieving efficient, precise, and stable cutting through differentiated transmission structures.

- Intelligent Sorting Feeding: Users sort ingredients based on their physical characteristics into corresponding dedicated feed ports—large root vegetables, small fruits/vegetables, leafy greens, or the universal inlet—for preliminary sorting.

- Independent Dual-Path Processing: Leafy greens are smoothly conveyed via an adjustable pressing belt into the high-speed chopping chamber, where ultra-high-speed dual-blade choppers deliver instantaneous, uniform cutting. Root vegetables enter the multi-functional rotating slicing chamber via the main conveyor belt, undergoing precise slicing according to the selected blade disc (dice, julienne, slice).

- High-Efficiency Synchronized Output: Both systems operate independently with separate power drives, working simultaneously without interference. Finished products are discharged through separate, smooth-flowing outlets to maximize throughput.

Technical parameters

| Model | WZ-688A |

| Voltage (V) | 220/380 |

| Power (KW) | 1.6 |

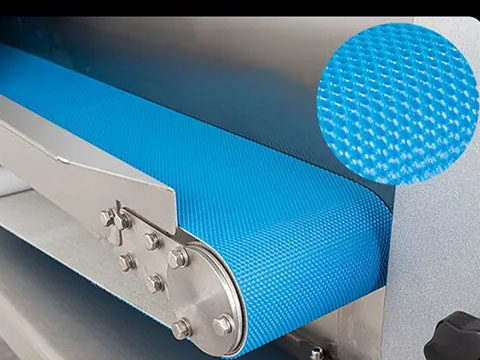

| Belt Width (mm) | 120 |

| Machine Output (kg) | 0-1000 |

| Dimensions (mm) | 1280X580X1060 |

| Machine Weight (kg) | 147 |

| Material | 304 stainless steel |

| Production Capacity | 1000kg/h |

| Cutting Results | Slice, shred, dice, slice, chop, ring |

| Packaging | Wooden frame/box |

| Diced Size (mm) | 8, 10, 12, 15, 20 |

| Shredded Size (mm) | 2, 3, 4, 5, 6, 7, 8 |

| Sliced Size (mm) | 2, 3, 4, 5, 6, 7, 8 |

Structural Components

- Modular Feeding System: Features three dedicated feed ports for preliminary ingredient sorting, enhancing processing efficiency and safety.

- High-Speed Leaf Vegetable Chopper: Utilizes durable double-blade choppers with synchronous belt drive, operating at 1104 RPM, specifically designed for rapid processing of soft leafy greens.

- Root Vegetable Multi-Function Blade Set: Includes four quick-change specialized blade discs (dicing, shredding, slicing, and large leaf vegetable blade). Features collision-resistant construction with a blade speed of 371 RPM, ensuring clean and uniform cuts.

- Reinforced Moisture-Resistant Transmission Components: All gears and sprockets undergo thickening treatment, significantly enhancing wear resistance and longevity in humid kitchen environments.

- Efficient Direct Drive Design: Key components utilize direct motor drive, eliminating redundant transmission stages for enhanced reliability and simplified maintenance.

- Waterproof Safety Enclosure: Electrical systems incorporate professional waterproofing and isolation from power circuits, substantially reducing failure risks.

- Quick-Release Modules: Single-side installation for the vegetable press belt and telescopic tensioning for the main conveyor belt enable disassembly and cleaning within 5 minutes without removing the main shaft.

- Wider Conveyor Belt: 120mm belt width paired with a vegetable press belt offering up to 100mm expansion accommodates a wider range of ingredient sizes.

- Precision Control Panel: Combination electrical switches provide clear tactile feedback and intuitive operation.