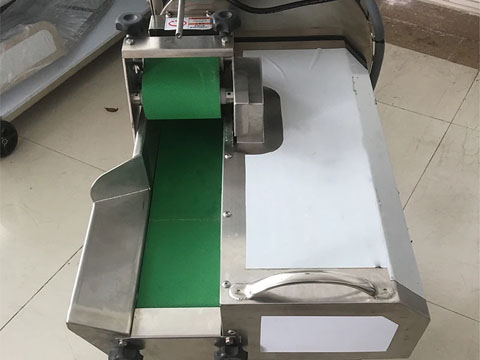

Commercial Dual-Inverter Vegetable Cutter

Introduction

This commercial dual-inverter automatic vegetable cutter adjusts cutting lengths with high precision, primarily slicing, dicing, and shredding. Beyond vegetables, it also processes medicinal herbs. Dual-inverter speed control allows customization of length, thickness, and width.

Constructed entirely from food-grade materials, this equipment complies with national food hygiene standards while balancing durability and ease of cleaning. It delivers professional vegetable cutting solutions for restaurants, cafeterias, fresh-cut vegetable processing plants, and similar settings.

Working Principle

- This machine employs a precision mechanical principle featuring dual motors operating independently yet in coordination. One motor controls the feeding speed of the screw auger, while the other independently regulates the cutting frequency of the forming blade.

- Through two variable frequency drives enabling stepless speed regulation for each motor, operators can independently and precisely adjust both the “filling extrusion speed” and the “meatball cutting and forming speed.”

- In high-speed mode, both systems operate at high speeds in coordination to achieve rapid, large-scale production. In low-speed mode, the extrusion and cutting actions become gentler, ensuring the filling is not overly compressed or damaged, resulting in meatballs that are denser and more uniformly rounded.

Technical parameters

| Model | WZ-681 | WZ-681S |

| Voltage (V) | 220/380 | 220/380 |

| Power (KW) | 0.85 | 1.3 |

| Belt Width (mm) | 120 | 120 |

| Machine Output (kg) | 500-800 | 1000-1500 |

| Dimensions (mm) | 770X460X1400 | 970X780X1600mm |

| Machine Weight (kg) | 70 | 135 |

| Material | 304 stainless steel | |

| Cutting Size | 1-60mm (adjustable) | |

Size Inverter Display Reference Table

| Cutting dimensions (mm) | 1 | 1.5 | 2 | 2.5 | 3 | 3.5 | 4 | 5 | 6 | 7 | 8 | 9 |

| Cutter frequency converter | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 38 | 30 | 25 | 22.5 | 20 |

| Conveyor frequency converter | 10 | 12 | 17 | 21 | 25 | 29 | 33 | 30 | 30 | 30 | 30 | 30 |

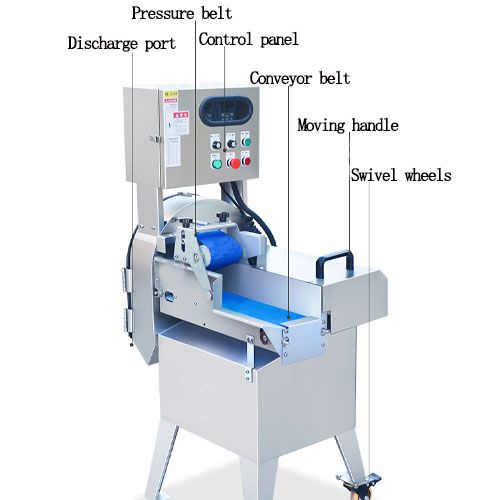

Structural Components

Intelligent Control Center

- Dual-Inverter Control Panel: Independently adjusts conveyor belt speed and blade disc rotation speed for intuitive control over cutting length and thickness.

- Transparent Safety Viewing Window: Enables real-time monitoring of the cutting process for enhanced safety and visibility.

- Safety Sensor Switch: Automatically shuts down when the cover is opened, ensuring absolute operational safety.

High-Efficiency Conveying and Holding System

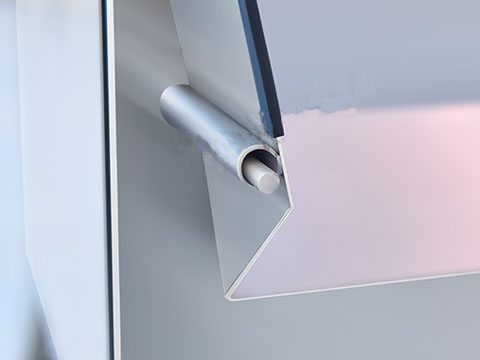

- Adjustable Pressure Belt: Height-adjustable to accommodate various vegetable sizes, gently presses without slipping or damaging leaves.

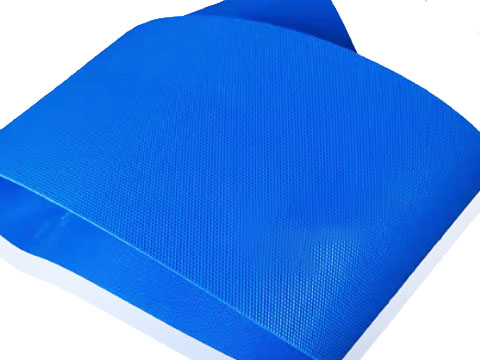

- Wide Wear-Resistant PU Conveyor Belt: Strong grip, smooth operation, easy disassembly for cleaning.

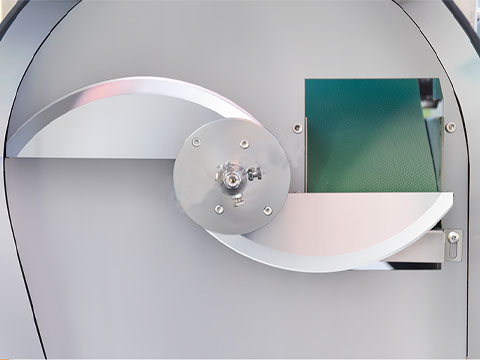

Core Cutting System

- Thickened Multi-Blade Precision Steel Cutting Disc: Forged from special steel, sharp and durable, delivers smooth cuts for neat vegetable surfaces and minimizes juice leakage.

- Optimized Airflow Design: Streamlined cutting chamber airflow combined with a flat, widened discharge port ensures smooth product ejection without jamming or splattering.

User-Friendly Body Design

- Integrated Thickened Stainless Steel Body: Sturdy and durable, meets food hygiene standards, and is easy to clean.

- Mobile Design: Equipped with heavy-duty swivel casters and a power-assisted handle for flexible movement and positioning within the kitchen.

Product Advantages

- Precision Cutting: High cutting accuracy enables millimeter-level specification control, ensuring uniform shape and size for every portion. This significantly enhances the visual appeal and professional presentation of dishes.

- User-Friendly Operation: One-touch start design paired with an intuitive control panel eliminates complex procedures. Beginners can master operation quickly without specialized training.

- High-Efficiency Output: Powered by a robust motor, a single unit can replace multiple skilled workers, swiftly processing large volumes of vegetables.

- Flexible Adaptability: Dual-inverter speed control allows free adjustment of cutting specifications to accommodate diverse vegetable preparation needs.

- Safe, Sanitary, and Durable: Entirely constructed from premium stainless steel with no hard-to-clean corners, ensuring thorough sanitation. Multiple safety protections provide dual safeguards for operator and food safety.

Application Scenarios and Core Uses

Application Scenarios

- Restaurant Kitchen Vegetable Prep: Chinese restaurants, Western restaurants, fast-food outlets, hotpot restaurants, home-style eateries, and other food service establishments.

- Group Catering & Cafeteria Prep: University cafeterias, corporate cafeterias, group meal providers, student nutrition meal distribution centers, and safe breakfast programs.

- Pre-cut Vegetable Processing & Distribution: Ideal for pre-cut vegetable processing plants and distribution companies, offering precise and efficient cutting services for vegetable pre-processing.

Core Uses

- Core Function: Efficiently cuts various vegetables, including leeks, celery segments, shredded Chinese cabbage, spinach segments, cilantro segments, shredded kale, scallion segments, chopped scallions, cucumber slices, sweet potato slices, and daikon radish slices.

- Extended Applications: Suitable for processing certain root vegetables (e.g., scallions, Chinese chive stems) and medicinal-food dual-use ingredients (e.g., cilantro, mint, perilla).

- Cutting Forms: Precisely processes into segments, shreds, slices, mince, and other forms to meet diverse culinary needs like stir-fries, cold dishes, soup garnishes, and salad bases.

Related Supporting Equipment

- Bubble Washer: Deep cleans vegetables and removes pesticide residues before cutting, enabling integrated “wash-cut” operations.

- Centrifugal Dehydrator: For vegetables used in cold dishes or salads, pair with a centrifugal dehydrator to rapidly remove surface moisture.

- Pre-cut Vegetable Packaging Machine: In pre-cut vegetable processing, combine cut and dehydrated vegetables with vacuum packaging machines or freshness-preserving packaging machines for portioning and sealing.

Why Choose Us?

Related Products

Multi Vegetable Cutter

Multi Vegetable Cutter Multi-functional vegetable cutter Introduction This commercial dual-head multi-function vegetable cutter is a…

Dual-speed Meatball Forming Machine

Dual-speed Meatball Forming Machine High-speed meatball forming machine Introduction The WZ-702 Dual-Speed Meatball Former is…

Commercial Meatball Forming Machine

Commercial Meatball Forming Machine Introduction Wanzhi Machinery’s WZ-605/605S compact commercial fully automatic meatball forming machine…

Potato Peeler Machine

Commercial Potato Peeler Introduction This commercial potato peeler is specifically designed for efficient and hygienic…

Industrial Fruit Vegetable Bubble Washer

Industrial Fruit and Vegetable Bubble Washer Introduction This fruit and vegetable bubble washer, also known…

Contact Us