Tahini Machine

Introduction

Wanzhi Machinery specializes in commercial tahini machine (colloid mills). Crafted from 304 stainless steel, they produce smooth, delicate sesame paste. These machines are commonly used in sesame paste workshops, central kitchens, food processing plants, and condiment factories.

We offer split-type colloid mills, vertical colloid mills, and horizontal colloid mills, all of which are easy to clean and corrosion-resistant.

- Capacity(kg/h): 10 – 15000

- Grinding Fineness: 100-600 mesh

Working Principle

The core principle is high-speed shearing, grinding, and emulsification.

- Feed: Pre-treated sesame seeds (such as those cleaned and roasted) enter the grinding chamber through the feed port;

- Shearing and Grinding: Inside the grinding chamber, there is a high-speed rotating disc and a fixed static disc, with an extremely small gap between them (adjustable to the micron level). As the sesame paste passes through this narrow gap, it is subjected to tremendous shear forces, friction, and high-frequency vibrations.

- Emulsification and Discharge: Under the powerful mechanical action, the solid particles in the sesame seeds are thoroughly broken down and refined, while the oil and solid components are forcibly mixed, forming a smooth and delicious sesame paste. Finally, driven by centrifugal force and the subsequent raw materials, it is discharged from the grinding chamber’s discharge port, completing the process.

Tahini Machines Technical Parameters

The most commonly used and ideal mill for sesame paste production is the vertical colloid mill.

| Model | JML-80 | JML-100 | JML-120 | JML-140 |

| Fineness (µm) | 2-40 | 2-40 | 2-40 | 2-40 |

| Capacity(kg/h) | 300-1000 | 500-2000 | 700-3000 | 1000-4000 |

| Power (kw) | 3 | 5.5 | 7.5 | 11 |

| Voltage (V) | 380 | 380 | 380 | 380 |

| Speed(r/min) | 2880 | 2900 | 2900 | 2930 |

| Dimensions (mm) | 360*360*820 | 410*410*960 | 410*410*960 | 500*500*1160 |

| Weight (kg) | 80 | 135 | 150 | 230 |

Recommended Combinations

| User Type | Supporting Solutions |

| Small sesame paste workshop (daily output 50-200kg) | Single Machine + Small Sesame Washing and Roasting Machine + Manual Filling Machine |

| Medium sesame paste factory (daily output 500-2000kg) | Dual Machine Linkage (Coarse Grinding + Fine Grinding) + Automatic Loading System + Filtering Device |

| Large food factory (daily output 5000kg or more) | Multi-Machine Production Line + PLC Control System + Automatic Filling Machine + Sterilization Equipment |

Advantages of Our Tahini Machines

- Extremely Fine Grinding: Our tahini machine utilizes 304 stainless steel grinding discs, achieving a grinding fineness of 10-23μm (100-600 mesh).

- Energy-Efficient, High-Performance: With a throughput of 10-15,000 kg/hour, it saves 30% energy compared to traditional stone mills, reducing your production costs.

- Food-Grade Safe Materials: All food-contact components are made of 304 stainless steel, making them easy to clean and corrosion-resistant.

- Multi-Purpose Machine, High Return on Investment: This machine not only makes tahini, but can also grind peanut butter, almond butter, chili sauce, soy milk, and more, helping you expand your business.

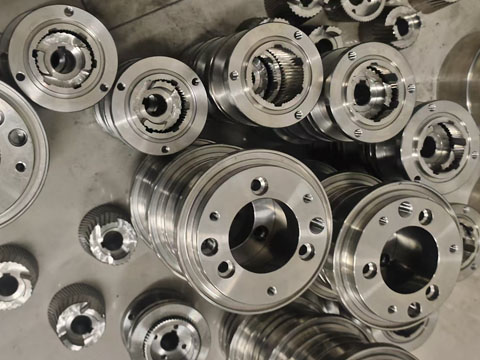

Structural composition

- Feed Inlet: The material entrance, typically connected to a feed hopper or pipe.

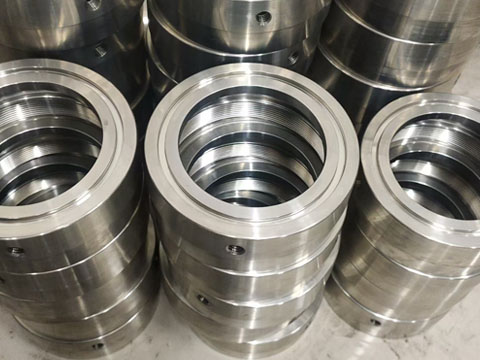

- Rotor: Connected to the motor’s main shaft, it rotates at high speeds (typically 3000 rpm or higher) driven by the motor.

- Stator: Stationary and precisely matched to the rotor. The tiny (adjustable) gap between the rotor and stator forms the grinding zone, where the material is sheared, ground, and emulsified.

- Adjustment: Used to finely adjust the gap between the rotor and stator. The smaller the gap, the finer the ground paste. This is a key device for controlling the fineness of the finished product.

- Motor: Provides the raw power required for grinding. High-performance motors are typically used to ensure stable speed and torque.

- Spindle: Connects the motor and rotor, accurately and stably transmitting the motor’s rotational power to the rotor.

- Discharge Outlet: The finely ground sesame paste flows out from this outlet.

Why This Machine is Perfect for Tahini?

Sesame seeds are rich in oil, placing extremely high demands on the shear force, cooling performance, and stability of the grinding equipment. Our tahini machine can solve the following problems:

- Sesame paste lamination: The machine uses a “high-frequency vibration + forced emulsification” process to fully blend the oil and solid particles in the sesame seeds. The finished product is stable for 30 days without the need for additional stabilizers.

- Difficulty in cleaning and resulting in flavor transfer: All parts that come into contact with the sesame paste (grinding chamber, feed inlet, and discharge outlet) are made of 304 stainless steel and are easily disassembled. After disassembly, they can be directly rinsed with a high-pressure water jet within 15 minutes, preventing flavor transfer in subsequent production runs.

- Summer sesame paste production can heat up and deteriorate: The optional integrated cooling system effectively controls the grinding temperature, preventing the loss of sesame aroma or protein denaturation due to high temperatures, and preserving the original flavor of the sesame paste.

- Clogging: The powerful motor and optimized flow channel design ensure smooth conveying and grinding of the high-viscosity sesame paste, preventing clogging and enabling continuous production.

Why Choose Us?

Our tahini machine is the core grinding equipment in a tahini production line. It seamlessly integrates with upstream equipment such as sesame roasters and coolers, as well as downstream equipment such as piston fillers and cappers, to form a complete automated system.

- Our tahini grinders have an extremely fine grinding fineness, reaching up to 600 mesh.

- Our colloid mills can grind not only sesame seeds, but also peanuts, nuts, seeds, and other products. We offer a comprehensive range of models and sufficient production capacity.

- We offer a wide range of colloid mills, including vertical, horizontal, and split-type colloid mills, offering a wide range of options and support customization.

As a professional colloid mill manufacturer, Wanzhi Machinery offers a variety of colloid mills, including vertical, split, and horizontal colloid mills. We also offer commercial and home colloid mills to meet various needs. If you require a colloid mill, please feel free to contact us.

Related Products

Nut Butter Grinder

Nut Butter Grinder Introduction Nut Butter Grinder Specialized for grinding various nut butters, achieving ultra-fine…

Chili Sauce Grinder

Chili Sauce Grinder Introduction Our commercial-grade chili sauce grinder utilizes advanced colloid milling technology and…

Commercial Peanut Butter Machine

Commercial Peanut Butter Machine Introduction Peanut butter ground by traditional peanut butter grinders often separates…

Horizontal Colloid Mill

Horizontal Colloid Mill Introduction A horizontal colloid mill features core components (stator and rotor) mounted…

Split Colloid Mill

Split Colloid Mill Introduction This type of colloid mill is called a split-type colloid mill…

Contact Us