Chili Sauce Grinder

Introduction

Our commercial-grade chili sauce grinder utilizes advanced colloid milling technology and is tailored for small and medium-sized food businesses seeking to increase efficiency, improve taste, and reduce operating costs.

Constructed from stainless steel, our chili sauce grinder offers high production efficiency, consistent quality, and the ability to grind a wide variety of materials, providing a high return on investment.

- Capacity(kg/h): 20 – 5000

- Material: 304 or 316l

Working Principle

- Coarse Grinding: Raw chilies (fresh or semi-dried) enter a wide inlet gap and are instantly crushed by the high-speed rotor.

- High Shear Refining: The material is forced through the narrow stator-rotor gap, enduring millions of shear cycles annually, pulverizing seeds and fibers.

- Homogenization: Centrifugal force propels the refined sauce through three precise stages, ensuring a uniform texture and stable emulsion.

Tahini Machines Technical Parameters

| Model | Production (kg) | Speed (r/min) | Power (kW) | Weight (kg) | Dimensions (mm) |

| WZ-80 | 50-80 | 2890 | 4 | 150 | 700*350*920 |

| WZ-110 | 150-200 | 2890 | 7.5 | 180 | 750*400*950 |

| WZ-130 | 200-400 | 2960 | 11 | 285 | 1000*450*1100 |

| WZ-160 | 300-700 | 2960 | 15 | 315 | 1000*450*1100 |

| WZ-180 | 600-1000 | 2960 | 18.5 | 340 | 1000*450*1150 |

| WZ-220 | 1500-2000 | 2960 | 30 | 800 | 1300*650*1400 |

| WZ-240 | 3000-5000 | 2960 | 37 | 1300 | 1400*600*1400 |

Traditional Chili Grinding Equipment vs. Colloid Mill Chili Grinder

| Comparison Items | Traditional chili pepper grinding equipment | Colloid Mill Chili Grinder |

| Grinding Precision and Taste | The crushing process is uniform, resulting in coarse particles, easily retaining chili seeds, and resulting in an uneven taste. | Adjustable precision, with three levels of fine grinding down to an ultra-fine finish, resulting in a silky, residue-free texture. Different textures can be switched with a single click. |

| Raw Material Utilization | Filtering is required to remove the seeds, resulting in approximately 20% of raw material waste and a loss of spiciness and flavor. | Almost 100% raw material utilization is achieved, with seeds and stems crushed and incorporated, enhancing the spiciness and flavor while directly reducing costs. |

| Product Stability | The chili peppers are prone to separation from the oil and sauce, resulting in a segregated texture. Uncrushed chili shells are prone to mold growth, shortening their shelf life. | Excellent homogenization and emulsification ensure a stable, non-separating sauce, and easier sterilization, effectively extending shelf life. |

| Operation and Adaptability | Processing high-viscosity materials is difficult, and cleaning is complex and time-consuming, impacting the efficiency of multi-batch production. | Highly adaptable, it can process both dry and wet chilies. Quick disassembly and cleaning in 5 minutes ensures hygienic efficiency and meets flexible production needs. |

Structural composition

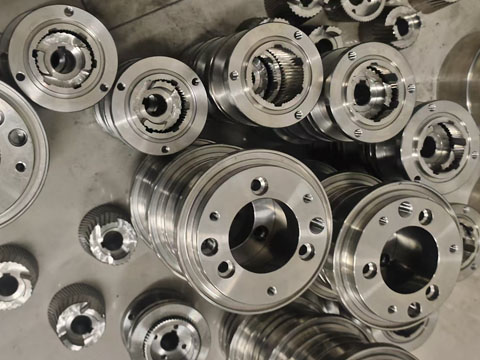

Stator and Rotor

- The stator and rotor are the core components of a colloid mill. By adjusting the gap between the stator and rotor, we can control the fineness of the chili sauce grind.

- Clockwise rotation generally decreases the gap between the stator and rotor, resulting in a finer particle size; counterclockwise rotation increases the gap and coarser particle size.

Other Components

Chili Sauce Production Equipment

The chili sauce grinder can be used independently or integrated with other equipment to form a chili sauce production line. The equipment required for chili sauce production is as follows:

- Bubble washer

- Crusher

- Colloid mill (grinder)

- Mixed Layer Kettle

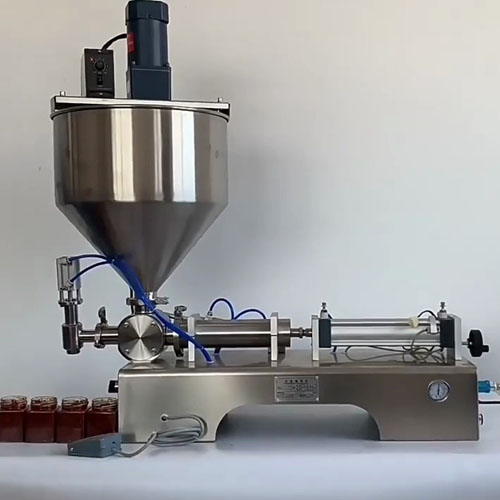

- Filling Machine

- Pasteurizer

Why Choose Us?

- High Product Quality: Made of high-quality stainless steel, it’s corrosion-resistant, hygienic, easy to clean, and has a long service life.

- Versatile Applications: Suitable for grinding ginger, garlic, tomatoes, and nuts, meeting market demand for diverse sauces.

- High Customization: Customizable components include the feed and discharge ports, stators, and rotors.

- Full Range of Specifications: We offer a wide range of colloid mills in various sizes, including vertical, split, and horizontal.

Wanzhi Machinery is committed to providing high-quality colloid mills to customers worldwide. Our colloid mills offer a variety of capacities to meet the production needs of large, medium, and small businesses. If you are interested in colloid mills, please contact us.

Related Products

Nut Butter Grinder

Nut Butter Grinder Introduction Nut Butter Grinder Specialized for grinding various nut butters, achieving ultra-fine…

Tahini Machine

Tahini Machine Introduction Wanzhi Machinery specializes in commercial tahini machine (colloid mills). Crafted from 304…

Commercial Peanut Butter Machine

Commercial Peanut Butter Machine Introduction Peanut butter ground by traditional peanut butter grinders often separates…

Horizontal Colloid Mill

Horizontal Colloid Mill Introduction A horizontal colloid mill features core components (stator and rotor) mounted…

Split Colloid Mill

Split Colloid Mill Introduction This type of colloid mill is called a split-type colloid mill…

Contact Us