Beer Mashing System Equipment

Wanzhi Machinery – Leading Supplier of Beer Mashing Equipment

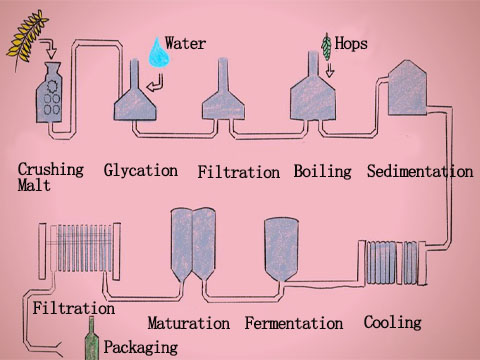

The essence of beer mashing is a precise biochemical process that systematically breaks down insoluble macromolecules—such as starch and proteins—in malt into soluble components like sugars, amino acids, and dextrins. This transformation relies on enzymes inherent to the malt or added enzyme preparations.

We have developed a comprehensive equipment system encompassing core reactions and auxiliary support. Through meticulous design details—including mechanically polished inner liners, precise temperature control, and custom-engineered plow blades—we ensure both wort quality and production efficiency. Furthermore, flexible combinations of two-, three-, and four-vessel configurations, dual heating options (steam or electric), fully or semi-automatic control modes, and custom features like automatic spent grain discharge and liftable plow blades enable seamless adaptation to brewing operations of varying scales.

Core Equipment for Beer Mashing

A complete mashing system is built around five core processes: mashing, lautering, boiling, clarification, and cooling. Each piece of equipment in these stages plays an irreplaceable role.

1. Mashing Tank

As the central vessel for malt conversion, it handles critical tasks such as mixing malted grains with mash and facilitating enzymatic reactions.

2. Beer Filter

Efficiently separates soluble wort from insoluble spent grains post-mashing, utilizing hot water (spent grain wash) to maximize sugar extraction from the spent grains.

3. Boiling Tank

Evaporates excess water to concentrate the wort; sterilizes; denatures and coagulates proteins; and, through hop addition, extracts bitter and aromatic compounds, establishing the foundation for the beer’s final flavor profile.

4. Clarifier/Sedimentation Tank

Utilizes fluid dynamics to rapidly settle hop residues and denatured proteins from boiled wort within minutes, yielding clear wort for cooling.

5. Plate Heat Exchanger

Performs critical wort cooling, reducing hot wort (above 85°C) to yeast inoculation temperature within tens of seconds.

6. Venturi Tube

Installed in the cooled wort pipeline, this serves as a critical component for wort transfer and mixing. It utilizes fluid dynamics to achieve efficient wort conveyance and blending of adjuncts.

Technical Specifications

| Model | Saccharification/Filtration (mm) | Boiling/Swirl Settling (mm) | Power (KW) | Material |

| WZ-200 | Φ910×1900 | Φ910×1900 | 25 | 304 |

| WZ-200 | Φ910×2300 | Φ910×2300 | 32 | 304 |

| WZ-200 | Φ1160×2300 | Φ1160×2150 | 45 | 304 |

| WZ-200 | Φ1360×2500 | Φ1560×2500 | 85 | 304 |

| WZ-200 | Φ1760X2500 | Φ1760X2500 | 120 | 304 |

| WZ-200 | Φ1960×2800 | Φ1960×2800 | 150 | 304 |

Our Advantages

- Core equipment features sanitary-grade stainless steel liners with mechanically polished surfaces. The high-gloss interior not only facilitates cleaning but also effectively prevents contaminant adhesion.

- We offer tiered equipment configurations—two-vessel, three-vessel, and four-vessel systems—ranging from compact workshop solutions like “mashing/boiling combination kettles + filter tanks” to large-scale production setups with “four-vessel independent configurations.”

- We provide tiered control system options—manual, semi-automatic, and fully automatic. Users can flexibly select based on their development stage, with upgrade interfaces reserved for future expansion.

Contact Us